Optilogic Blog Posts

Lead Through the Shift: How Bold Supply Chain Design Turns Tariffs into Opportunity

Turn the new Trump tariffs into opportunity with supply chain design. Don’t wait for problems—use scenario planning for disruptions like tariff shocks, simulate possible outcomes, and create contingency playbooks to mitigate cost and risk.

From Chaos to Strategy: An AI-Adoption Framework Every Supply Chain Exec Needs to Know

Discover W.I.S.E. A.T. A.I., a practical, human-centered framework by Megan Torrance for adopting AI in the supply chain. Learn how to move from chaotic experimentation to scalable, responsible AI strategies that empower teams and drive real impact.

Why We Do What We Do: A CEO’s Take on Purpose, Design, and Real Impact

Explore key insights from Optilogic CEO Don Hicks’ OptiCon keynote, covering the company’s purpose-driven mission, the role of design in supply chain innovation, and the cultural values that drive real impact across teams and enterprises.

How Optilogic’s Lumina Tariff Optimizer Helped Avoid $8M in Tariff-Driven Supply Chain Costs

Discover how a global manufacturer avoided $8 million in tariff-driven costs using Optilogic’s Lumina Tariff Optimizer. Learn how rapid scenario modeling and global supply chain redesign helped unlock real, bottom-line savings.

Trump Watch: How New Presidential Energy Policies Will Impact Your Supply Chain Design

Trump signed several executive orders that directly affect U.S. energy policy just on his first day in office. Here’s what supply chain executives need to know about how the Trump 2.0 energy policies will influence supply chain design.

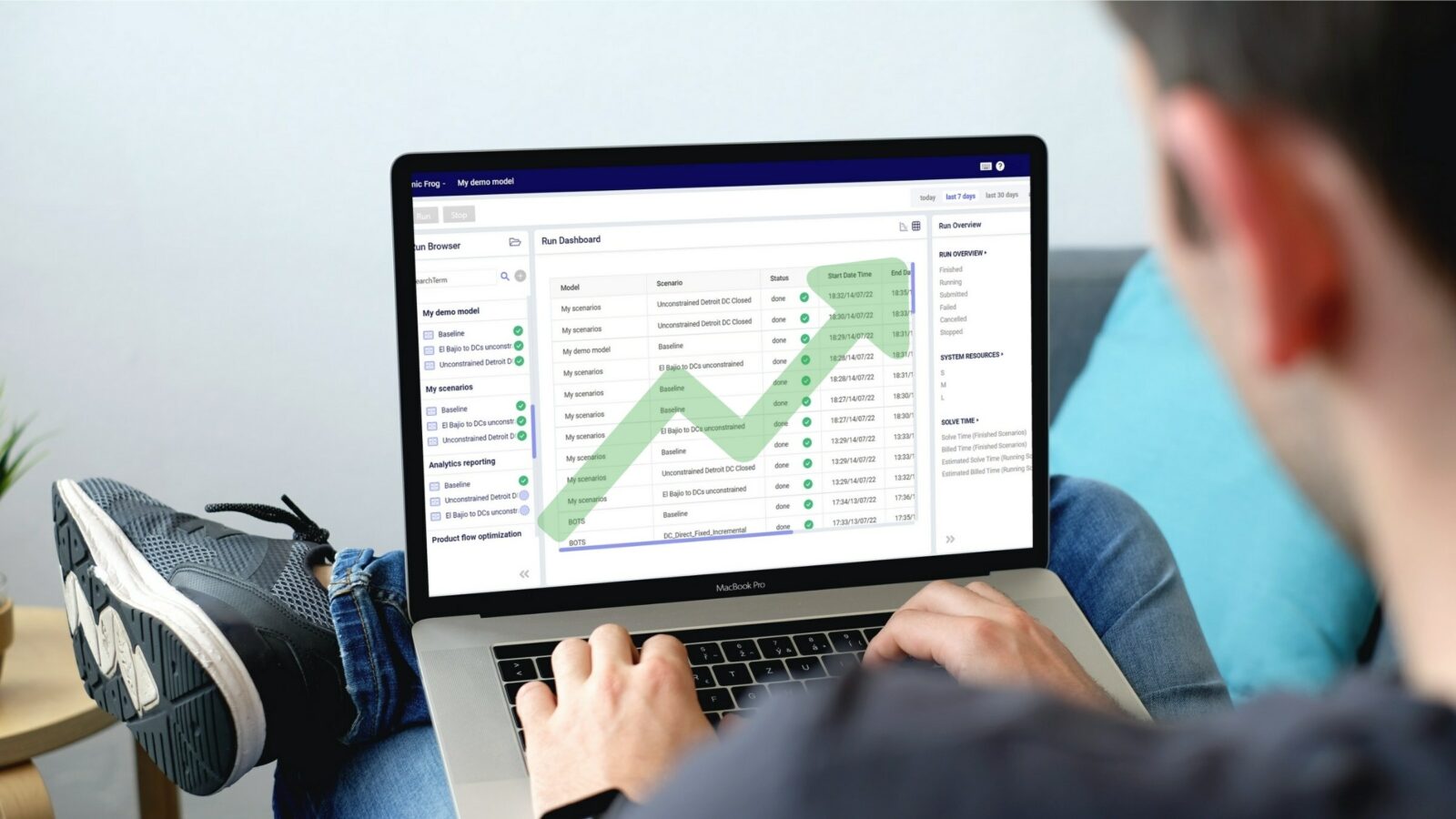

What’s New in Optilogic? Product Update March 2025

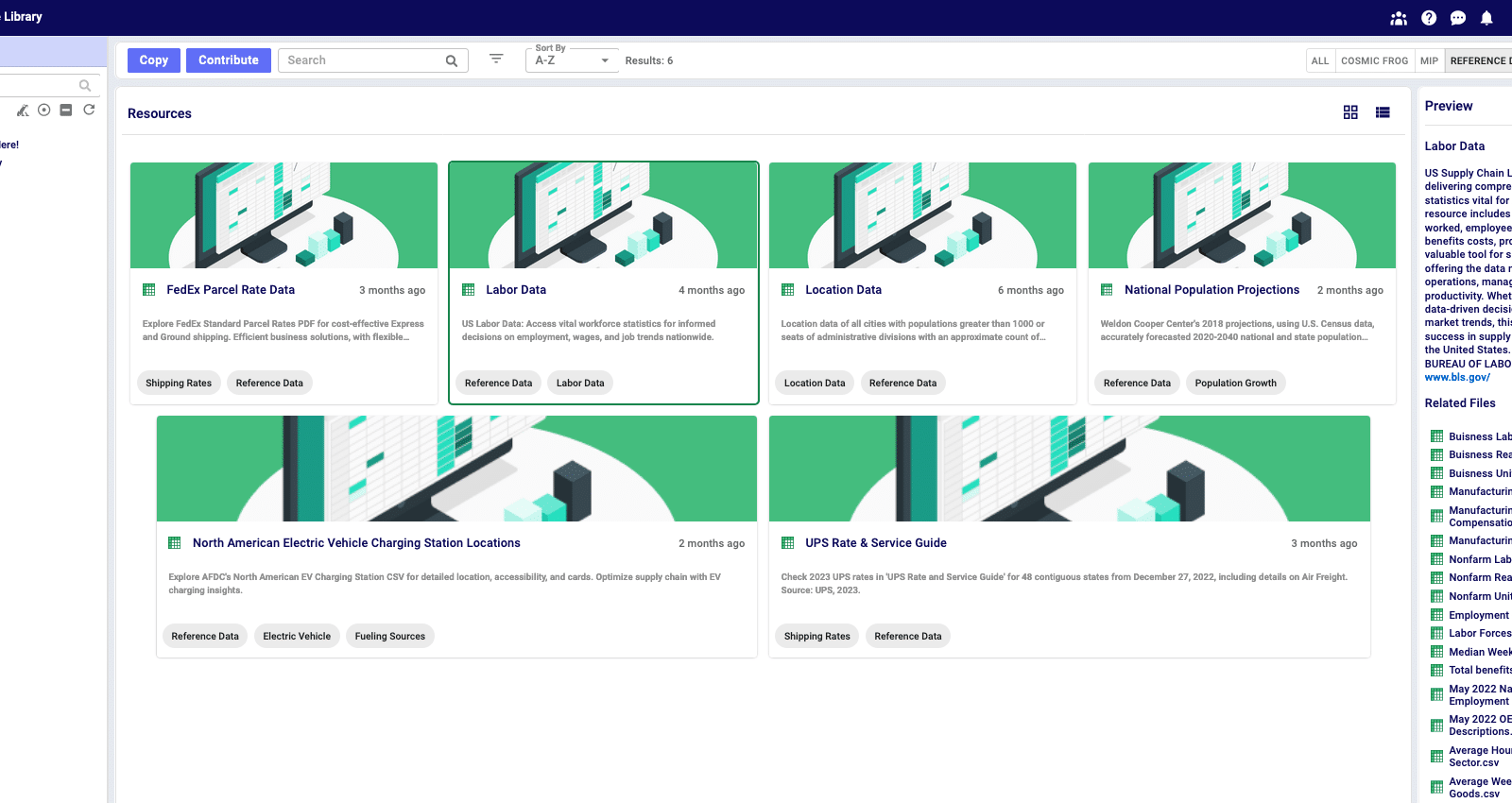

Discover the latest enhancements in Cosmic Frog with our March 2025 product update. Updates include scenario engine tagging in resource library templates, technology defined by scenario, Excel app builder updates and technology updates for network optimization and transportation optimization.

5 Important Reasons to Define your Inventory Policies

Inventory policies and rules play a critical role in your organization’s supply chain design. Getting these factors right is essential to customer service levels and cost efficiency. Here’s how and why to define inventory policies and rules for your business.

From Reactive to Proactive: Embracing Continuous Supply Chain Design

There’s been a lot of talk recently about “continuous supply chain design” from planning vendors. The problem is the technology they are touting is a parlor trick. Here’s how true continuous supply chain design works and how to take the first step.

Taxes and Duties: The Hidden Impact on Supply Chain Design

Explore how taxes and duties influence supply chain design, affecting not only cost but also service levels and risk. Understand the intricate ways in which different tax regimes can shape logistical decisions and overall supply chain efficiency. Learn effective strategies for integrating tax considerations into your planning processes to optimize performance and enhance profitability.

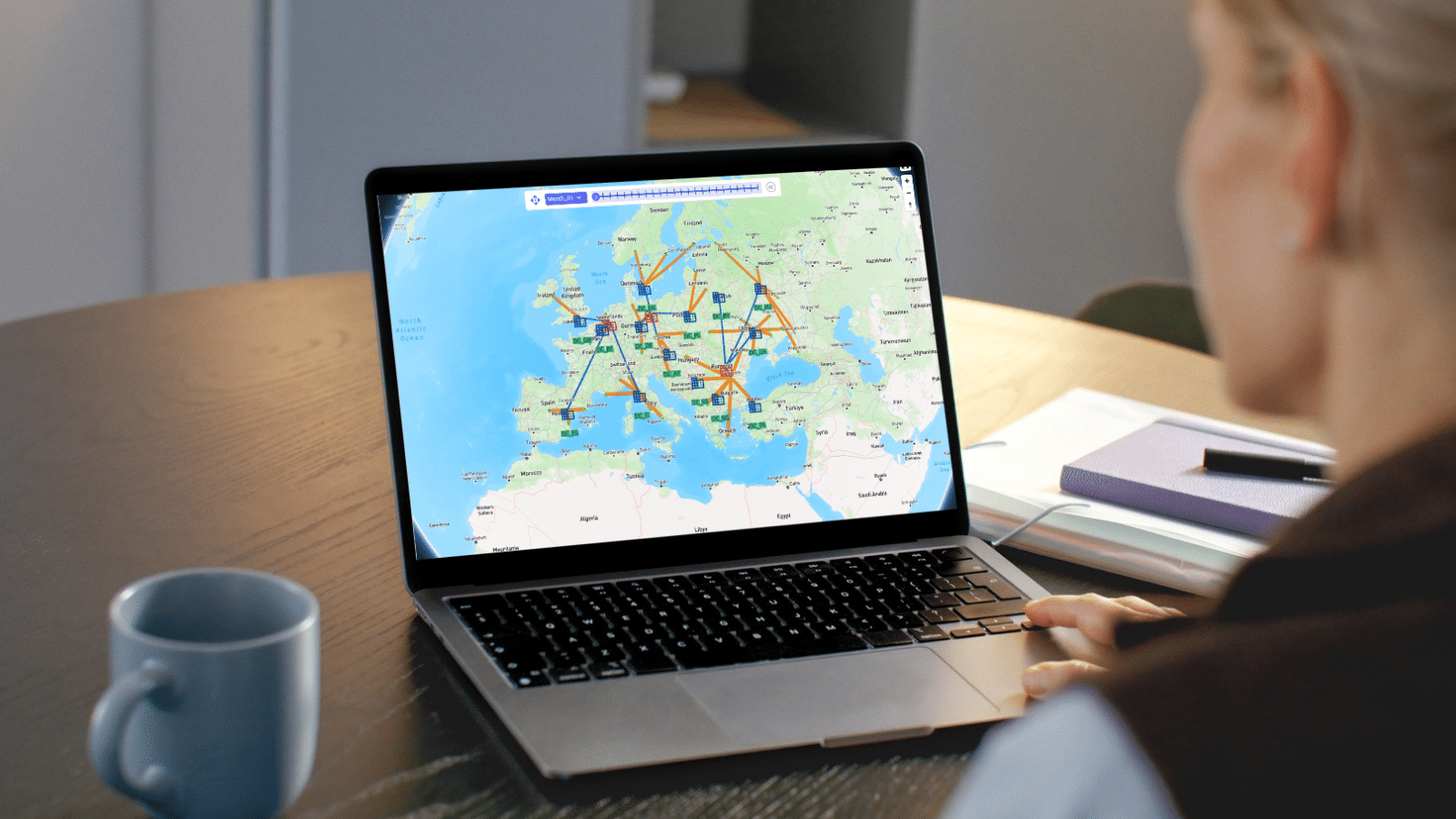

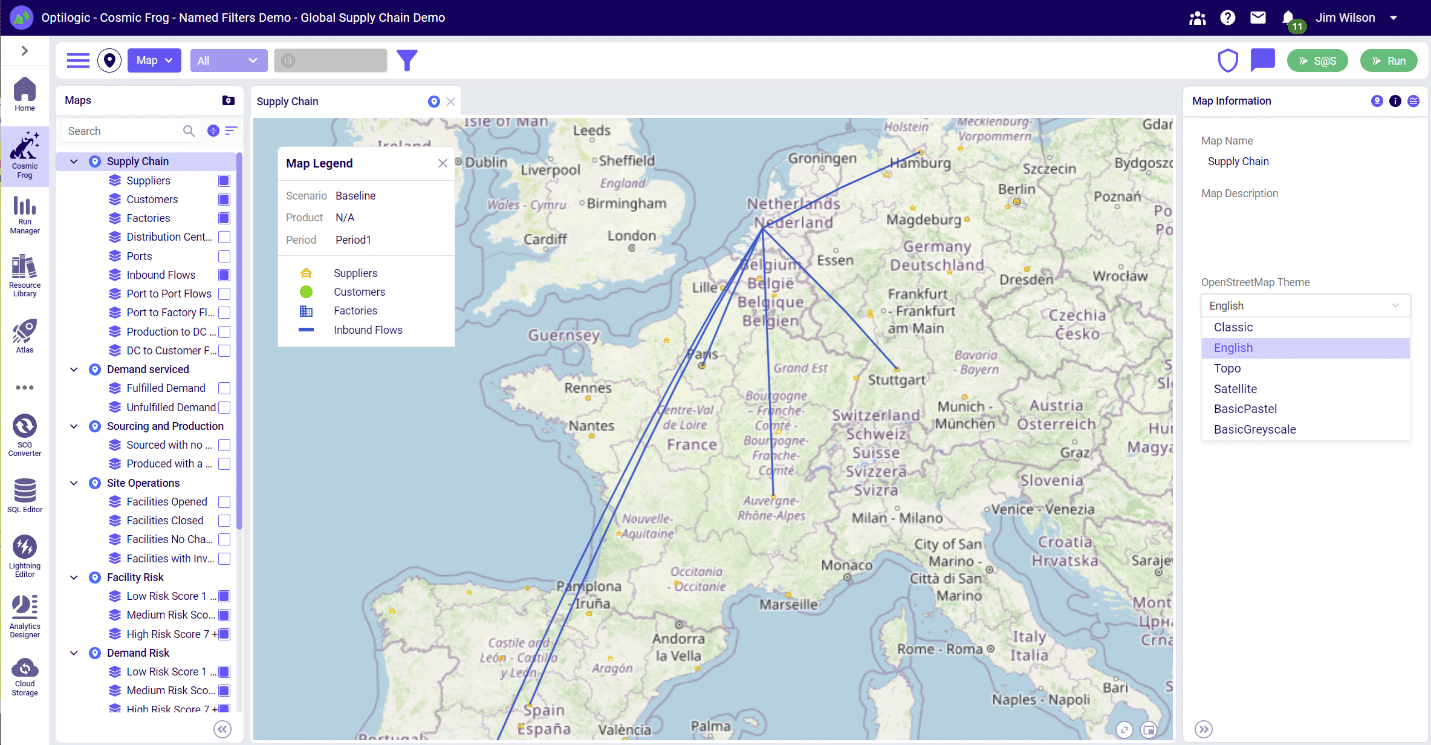

Geopolitical Disruptions: Preparing Your Supply Chain for Global Uncertainty

This blog post discusses strategic preparedness for geopolitical disruptions, highlighting supply chain design and empowering decision-makers. Discover actionable insights and innovative solutions to enhance resilience and agility in your organization’s supply chain amidst global uncertainty.

Key Supply Chain Design Trends Transforming Asia’s Market

Discover how intelligent supply chain design enables executives to evaluate cost, service, risk, and sustainability trade-offs of changes to global supply chains. Explore case studies and strategies shaping the future of supply chains in Asia and around the world.

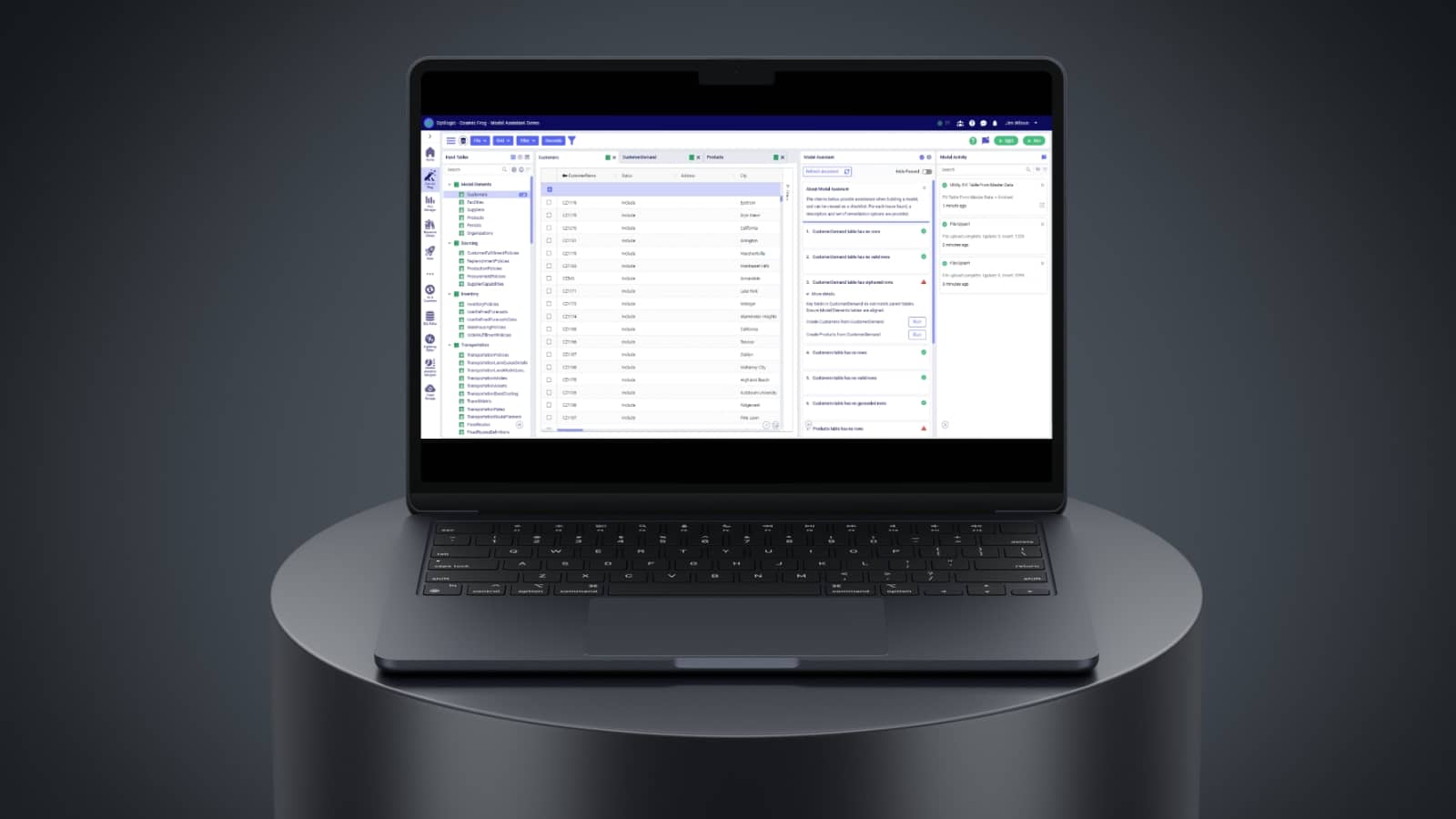

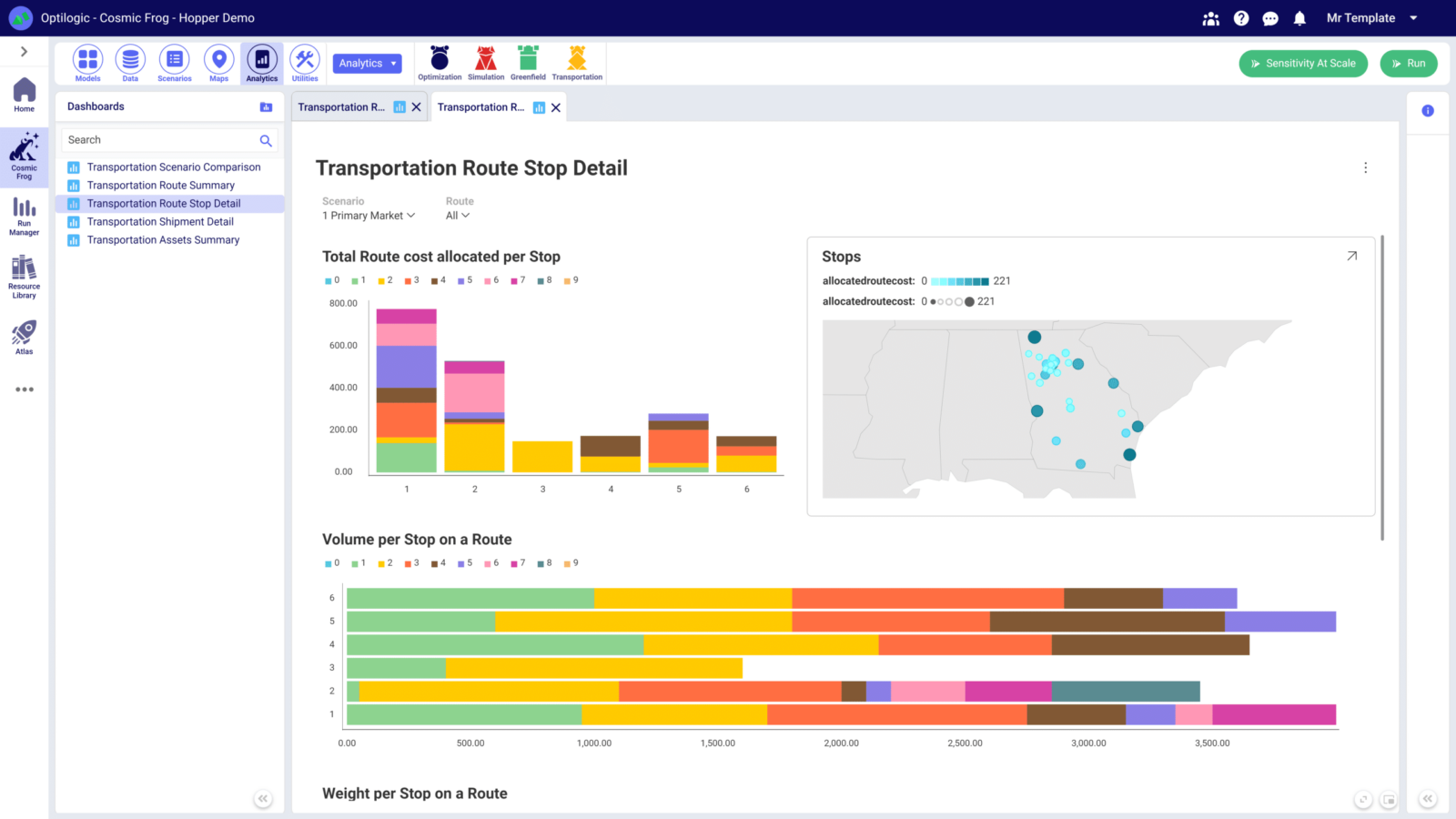

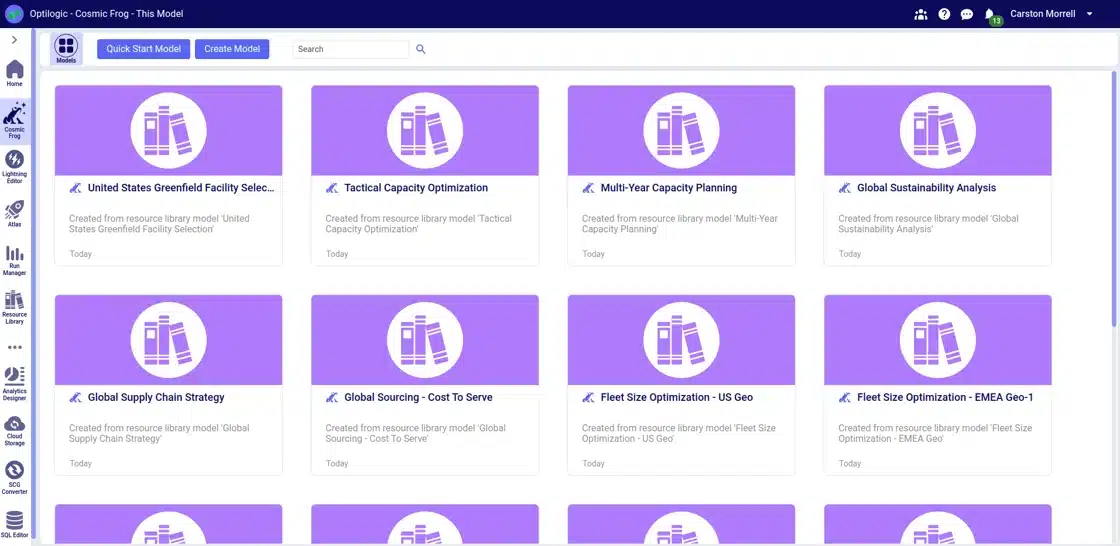

Drive Value Faster with Six Innovative Supply Chain Modeling Tools in Cosmic Frog

Discover how these six innovative modeling tools within Cosmic Frog revolutionize supply chain design, driving efficiency and value in complex environments. Transform your operations, streamline processes, and enhance decision-making with our game-changing solutions.

Supply Chain Simulation Explained

Supply chain simulation is the most granular modeling technique. This preferred method for service level analysis shows how business rules, policies, product requirements, etc. impact demand, manufacturing cycle times, staffing requirements, transportation lead times, and more. These insights can be instrumental for a multi-tiered supply chain’s inventory strategy.

Is Supply Chain Design for Mid-Market Companies Too?

Mid-market company supply chains grapple with many of the same challenges large companies face. Here’s why supply chain design is crucial to the future success of mid-market companies and how they can take advantage of the same technology and benefits as their Fortune 100 counterparts.

Revealed: 6 Must-Know Tips for Evaluating Supply Chain Design Solutions

Discover six crucial tips for evaluating supply chain design solutions and ensure you select the best fit for your company. Learn about ease of integration, advanced analytics, customization, and expert support to optimize your supply chain strategy effectively.

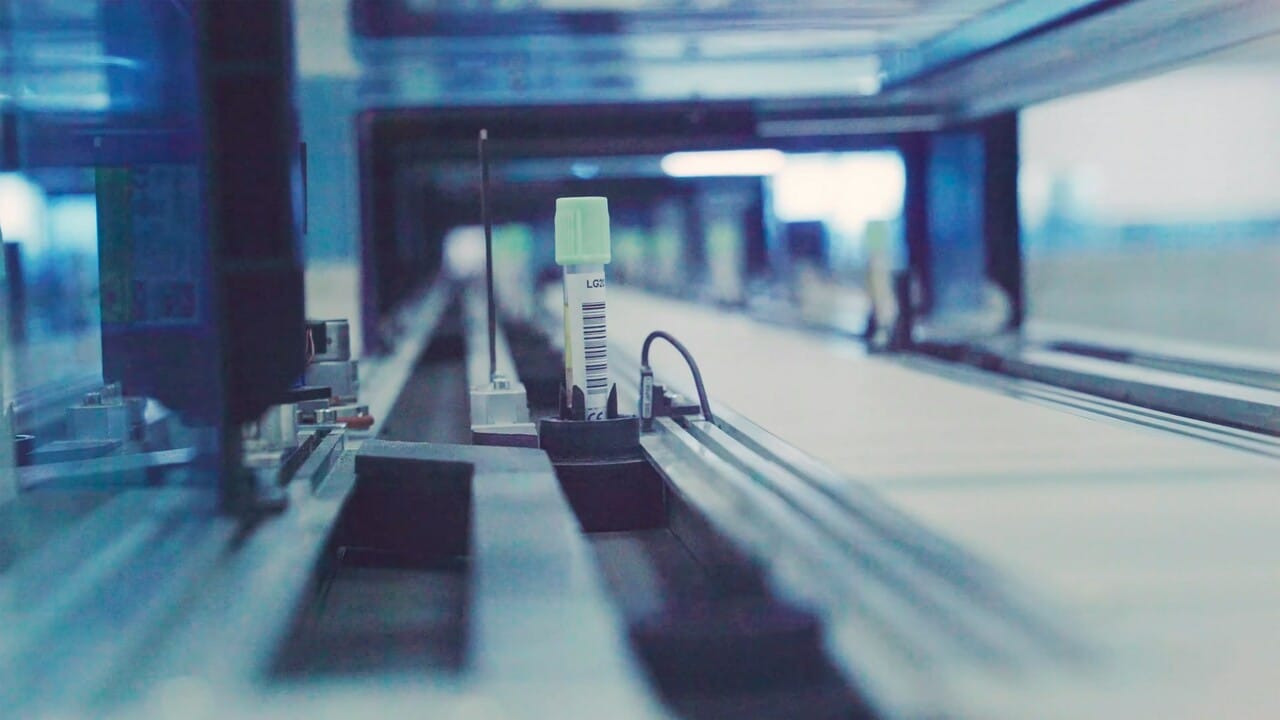

Redefining a Life Sciences Distribution Network using Supply Chain Design

Argon & Co. and Optilogic teamed up to help a life sciences client redefine their distribution strategy to adapt to manufacturing changes, reduce costs, and enhance customer service. This article explains how we approached the project and why we selected Optilogic Cosmic Frog as the supply chain design solution.

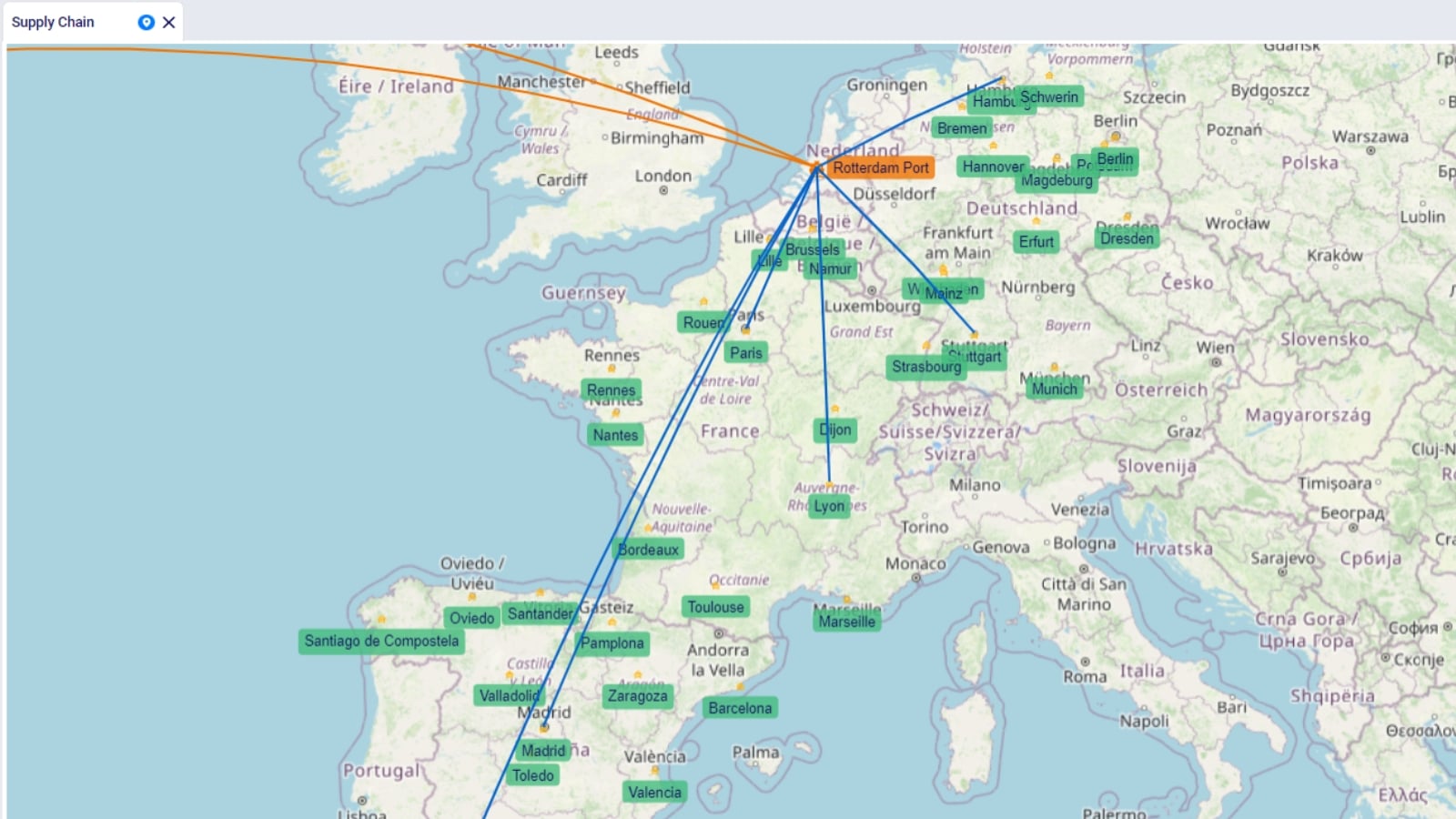

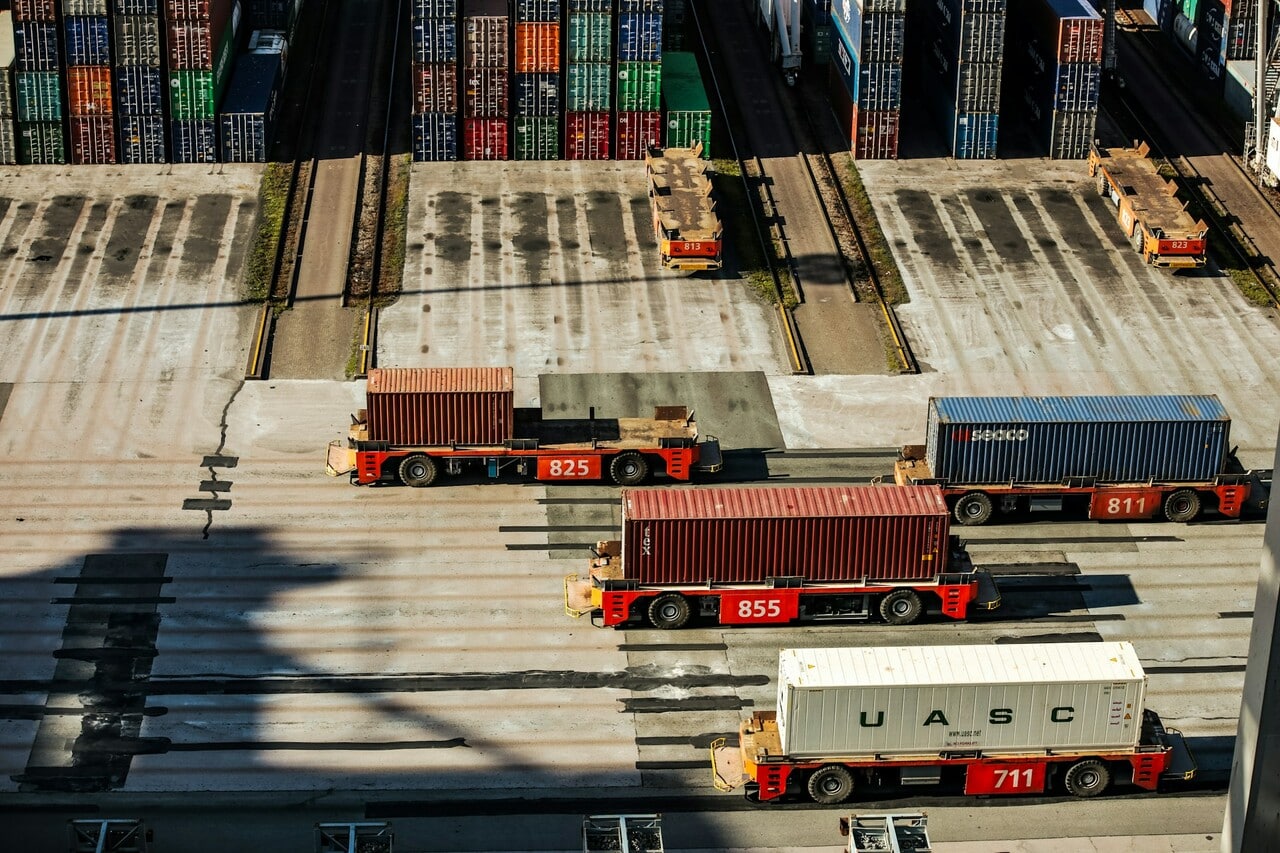

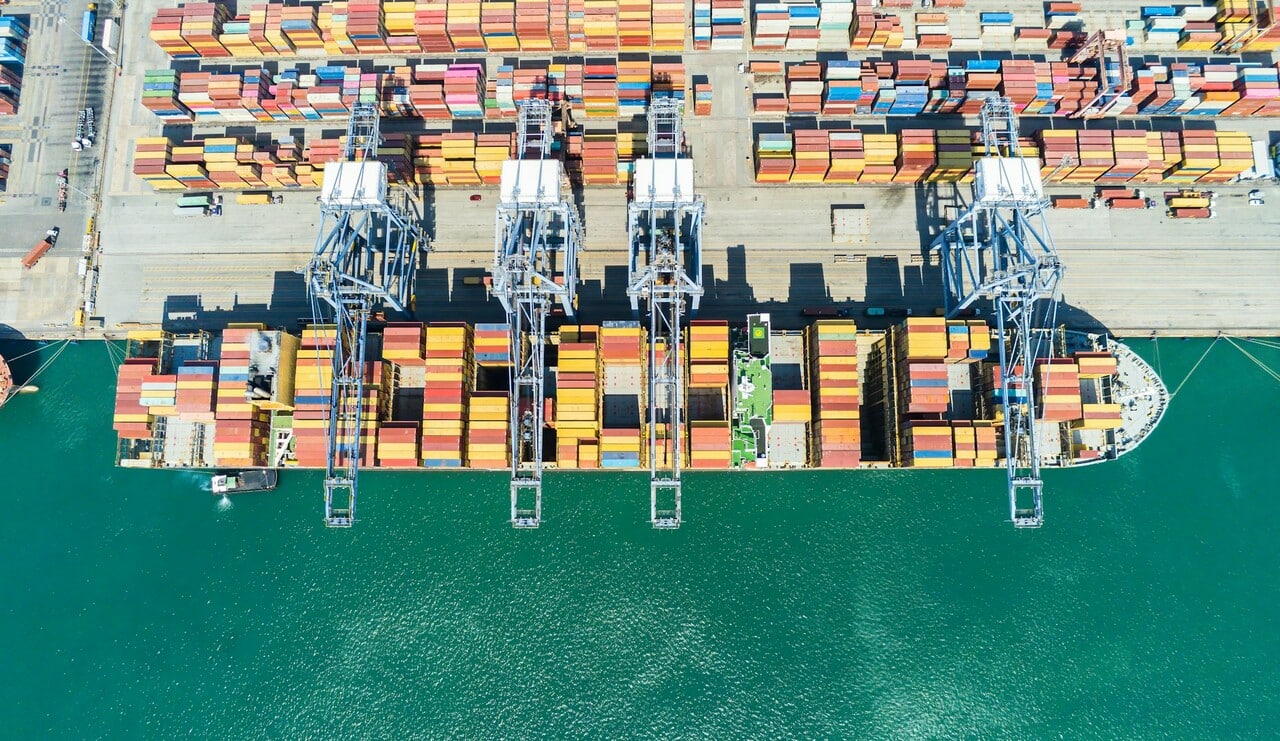

How Supply Chain Design Addresses the Global Impacts of Port Congestion

Explore how supply chain design tackles the pressing issue of global port congestion, delving into strategies, technologies, and innovations that optimize logistical pathways, mitigate disruptions, and ensure smooth operations in the face of evolving challenges.

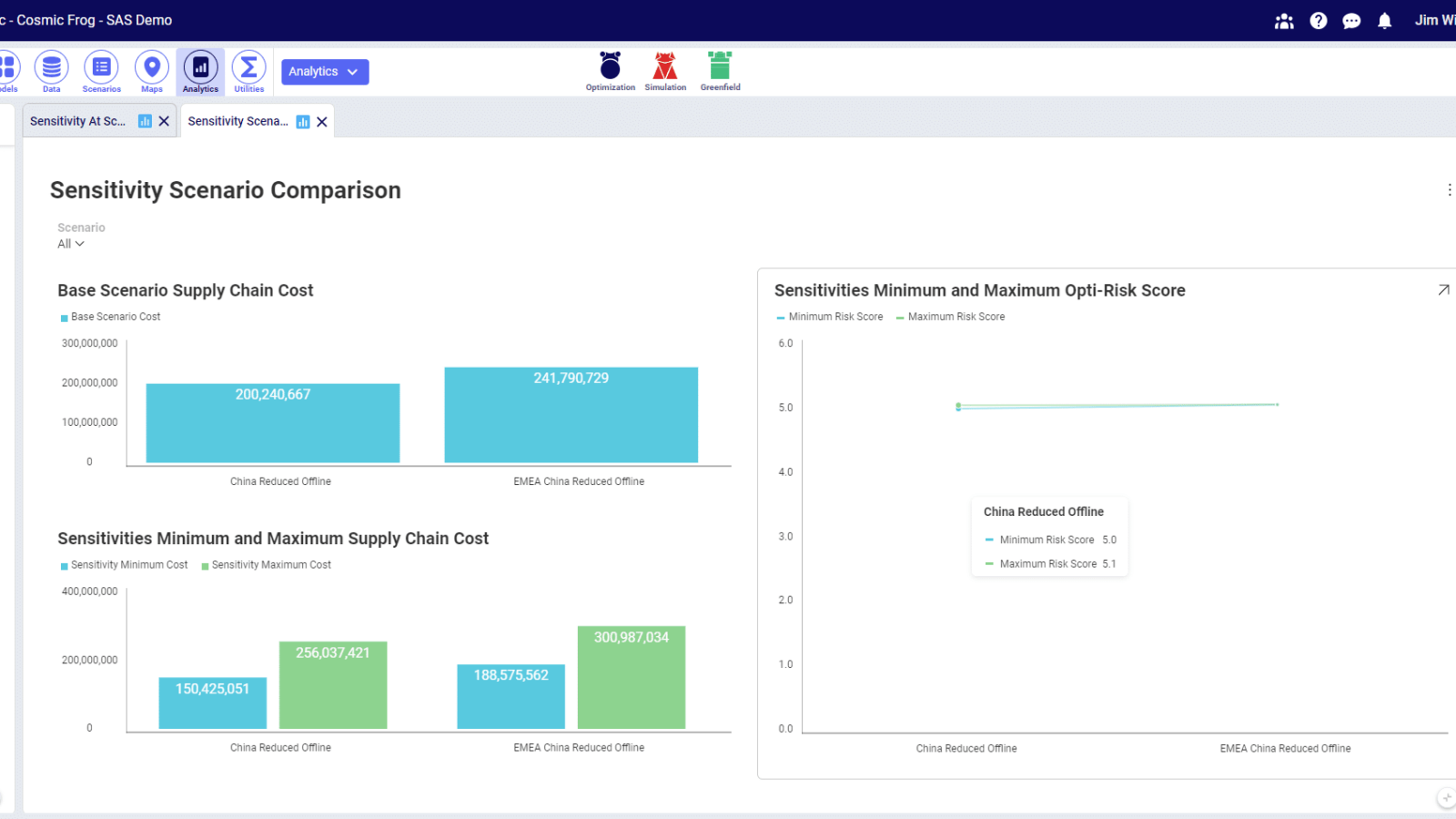

Sensitivity at Scale: Run Thousands of Sensitivity Scenarios in Parallel with a Single Click

Learn how to use Cosmic Frog Sensitivity at Scale: Automatically create hundreds or thousands of sensitivity scenarios and rapidly analyze on Optilogic’s supply chain design platform to select the most resilient designs.

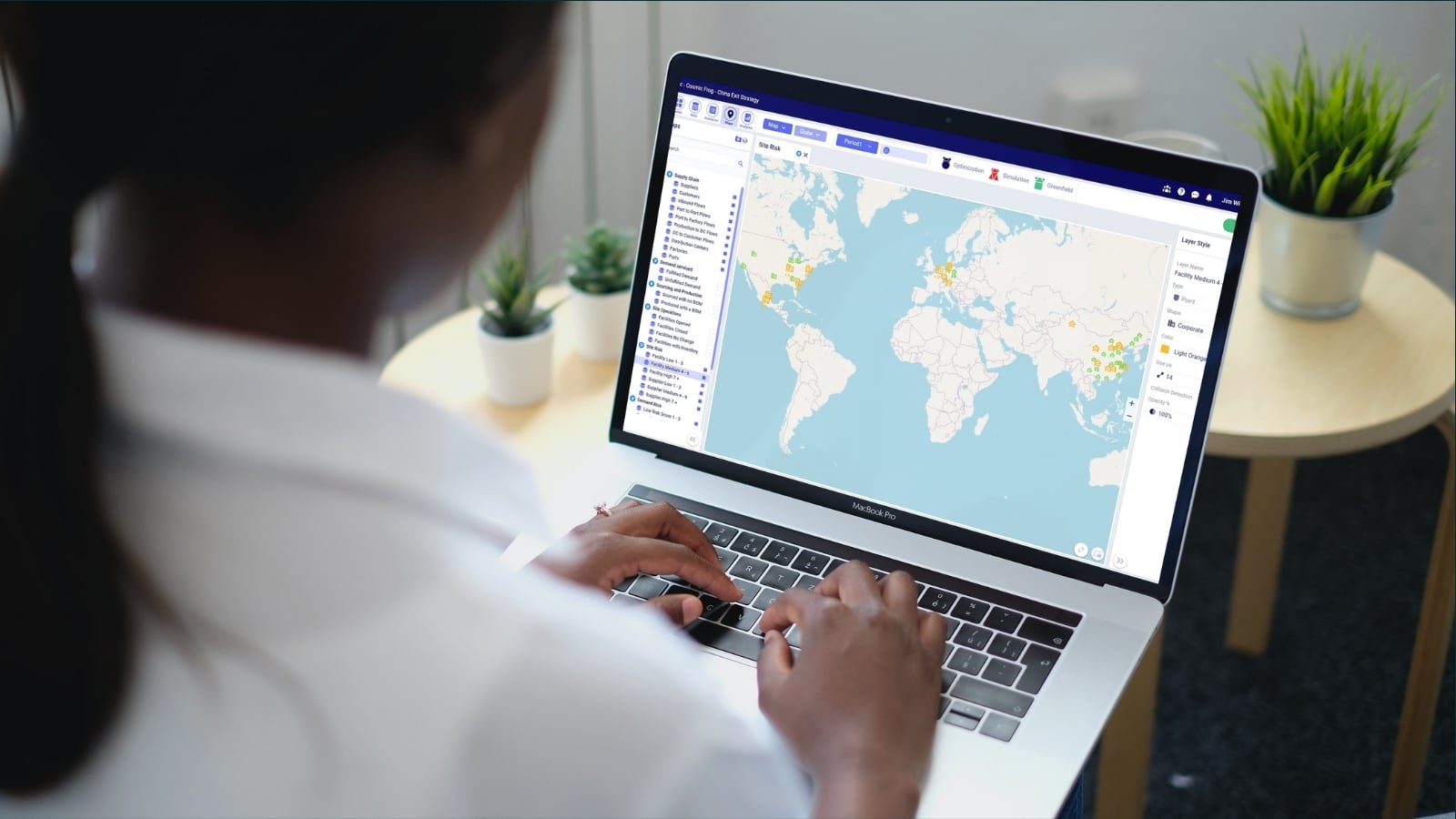

Should You Move Your Supply Chain Out of China? How to Evaluate a Nearshoring Strategy

An increasing number of U.S. companies are evaluating how to move all or part of their supply chain out of China to increase resiliency. Here’s how to model your China supply chain exit strategy to reduce risk and improve service.

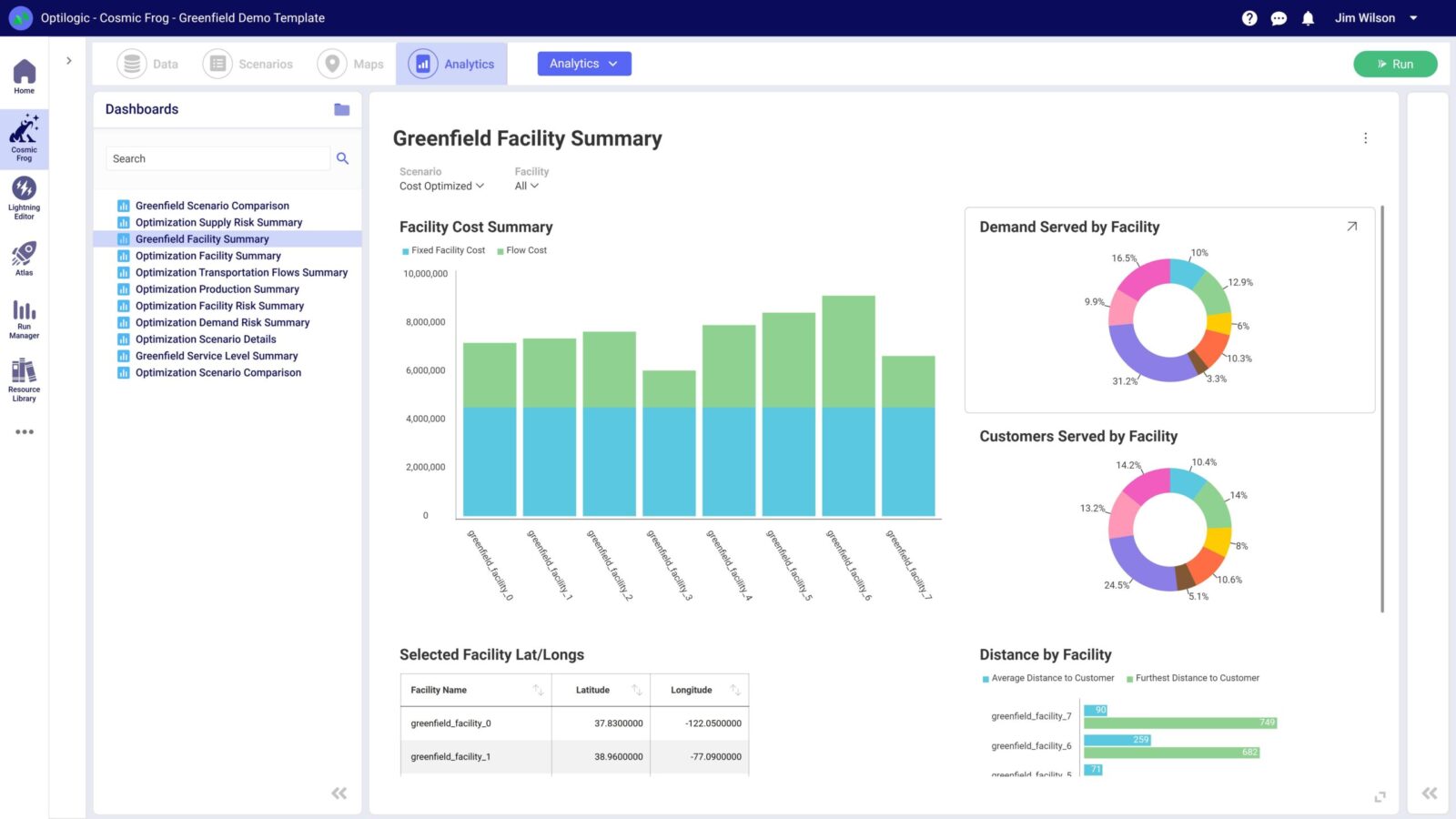

Intelligent Greenfield Analysis: The Fastest Path to Network Design in 2024

When planning for new facilities or market expansion, reducing transportation expenses and emissions without sacrificing customer service is a tricky problem to solve. The obvious solution is through reducing the distance between you and your customers, but you can’t run an unlimited number of distribution centers.

Finding the balance between unlimited distribution centers and high transportation costs requires some serious math—how do you narrow down site options before you get into the optimization model? That’s where greenfield analysis comes in.

Trends in the Automotive Industry in 2024

The automotive industry has experienced high volatility in recent years. The pandemic all but halted manufacturing across nearly every industry, including automotive. In 2024, the automotive industry is experiencing new trends shaping behaviors at every step along the supply chain.

This article explores trends in the automotive industry in 2024 and how companies can take advantage of these trends to see greater success.

Inventory Planning and Management: How to Build Inventory Strategies for Your Organization

Inventory drives revenue (and success) for your organization, and for many companies, inventory is the primary revenue stream. As a result, inventory management and planning must be a priority. Explore the best practices for inventory management.

How to Jump into the Optilogic Supply Chain Design Frogger Pond Community

Frogger Pond is the premier online destination for supply chain designers to share best practices, connect with peers, and contribute to thought leadership. We’re thrilled to announce that our platform is live and ready for you to explore.

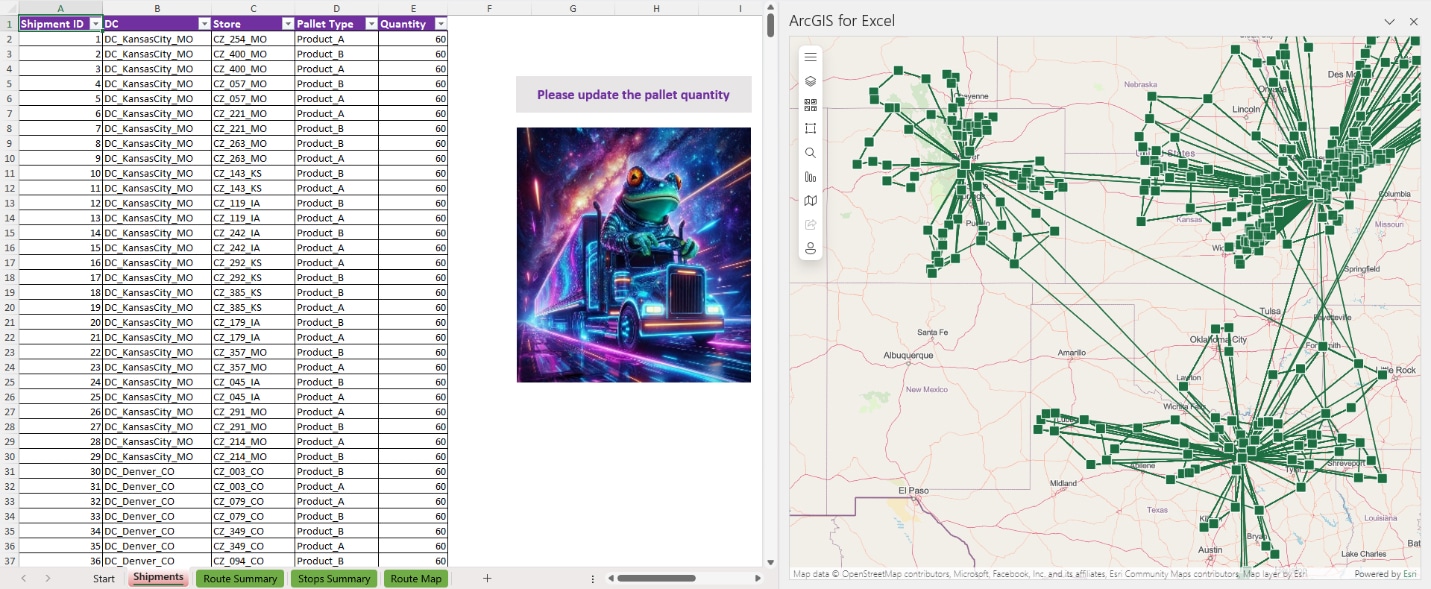

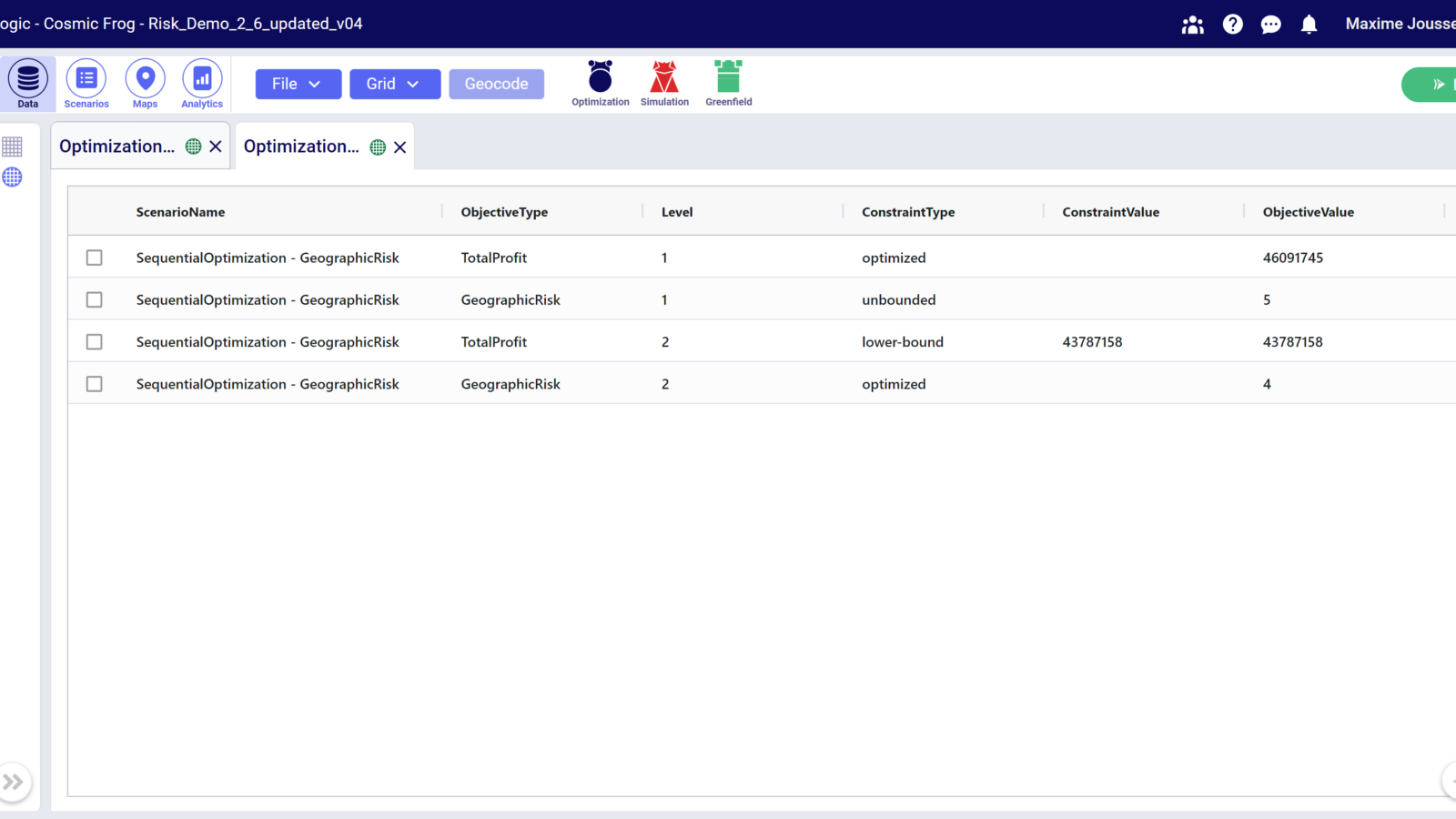

Step-by-Step Guide to Sequential Optimization

Sequential optimization is a powerful optimization technique used in supply chain modeling. It involves breaking down a multi-objective optimization problem into a series of single-objective sub-problems. Here’s how to use sequential optimization in Cosmic Frog.

What Is Nearshoring? A Guide for Resilient Manufacturers

Nearshoring isn’t just a buzzword. The pandemic highlighted a dire need for supply chain resilience across the board.

While supply shortages, bottlenecks, and crazy-long lead times hurt, they painted a clear picture of what your supply chain needs going forward. For many, that picture looked a lot like the map of North America.

What’s the Difference Between Supply Chain Design and Supply Chain Planning?

Your supply chain strategy is central to your success. Both supply chain design and supply chain planning fall within ‘supply chain management’. Both concepts, with differing focuses and objectives, are essential for the successful operation of a supply chain.

Supply Chain Modeling: Tips for Getting Started

An organization’s supply chain is foundational to day-to-day and long-term operations. Intentional and strategic supply chain design empowers businesses to understand how to operate most effectively, efficiently, and intentionally to hit target KPIs and meet various organizational goals.

Benefits of Network Design in Supply Chain

Your supply chain network design ensures your organization has defined, created, and optimized the ideal supply chain for your needs. Effective supply chains require intentional network design, and Optilogic’s platform empowers you to create and implement those smart supply chain designs.

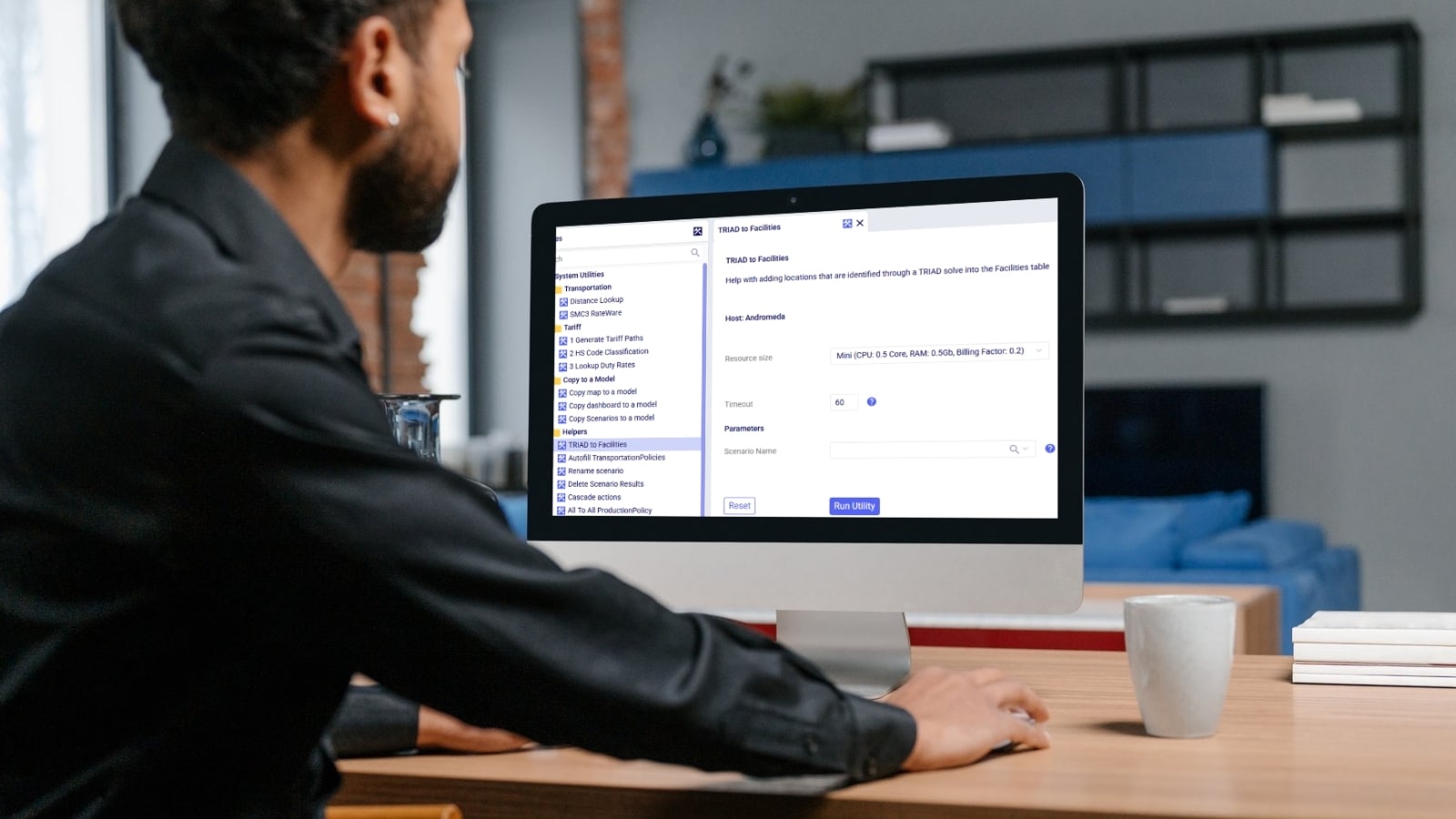

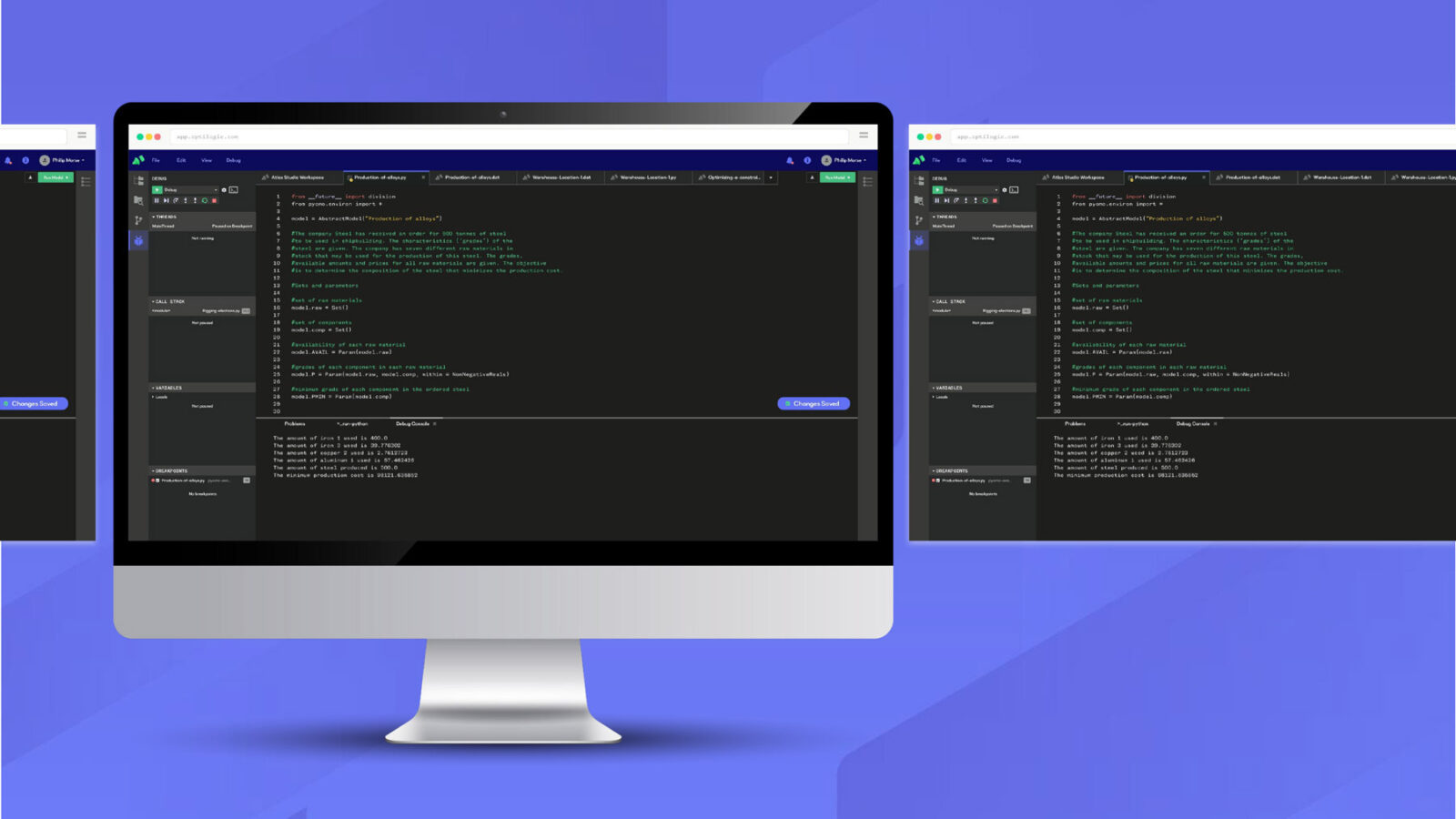

Q&A: The Optilogic Atlas Extensible Platform

Optilogic Cosmic Frog is the fastest and best choice for supply chain network design within a simplified user interface. For skilled modelers and developers who want to create custom applications or tailored workflows to fit specific business problems, the Optilogic Atlas developer platform is the perfect solution.

How to Build a Supply Chain Design Center of Excellence

Your supply chain design center of excellence (COE) empowers your organization to hit its targets through balanced, sustainable, resilient supply chain design. Building your COE requires strategic intentionality to create a team that understands your organizational culture, goals, and potential. Here’s how to build a COE that drives success.

Capital Expenditure Planning for Mergers and Acquisitions

As your organization embarks upon capital expenditure (CapEx) planning, you want data-driven insights to guide your decision-making. This article from the Optilogic team explores capital expenditure planning for mergers and acquisitions and walks through various best practices to help you execute a CapEx plan that leads to long-term growth and success.

Industry Guide to Supply Chain Network Design

If your business has a physical supply chain, supply chain network design is central to your success. By understanding and optimizing supply chain network design, you positively impact every aspect of your business. Read on to learn the goals, benefits, and best practices of supply chain network design that will help your organization thrive.

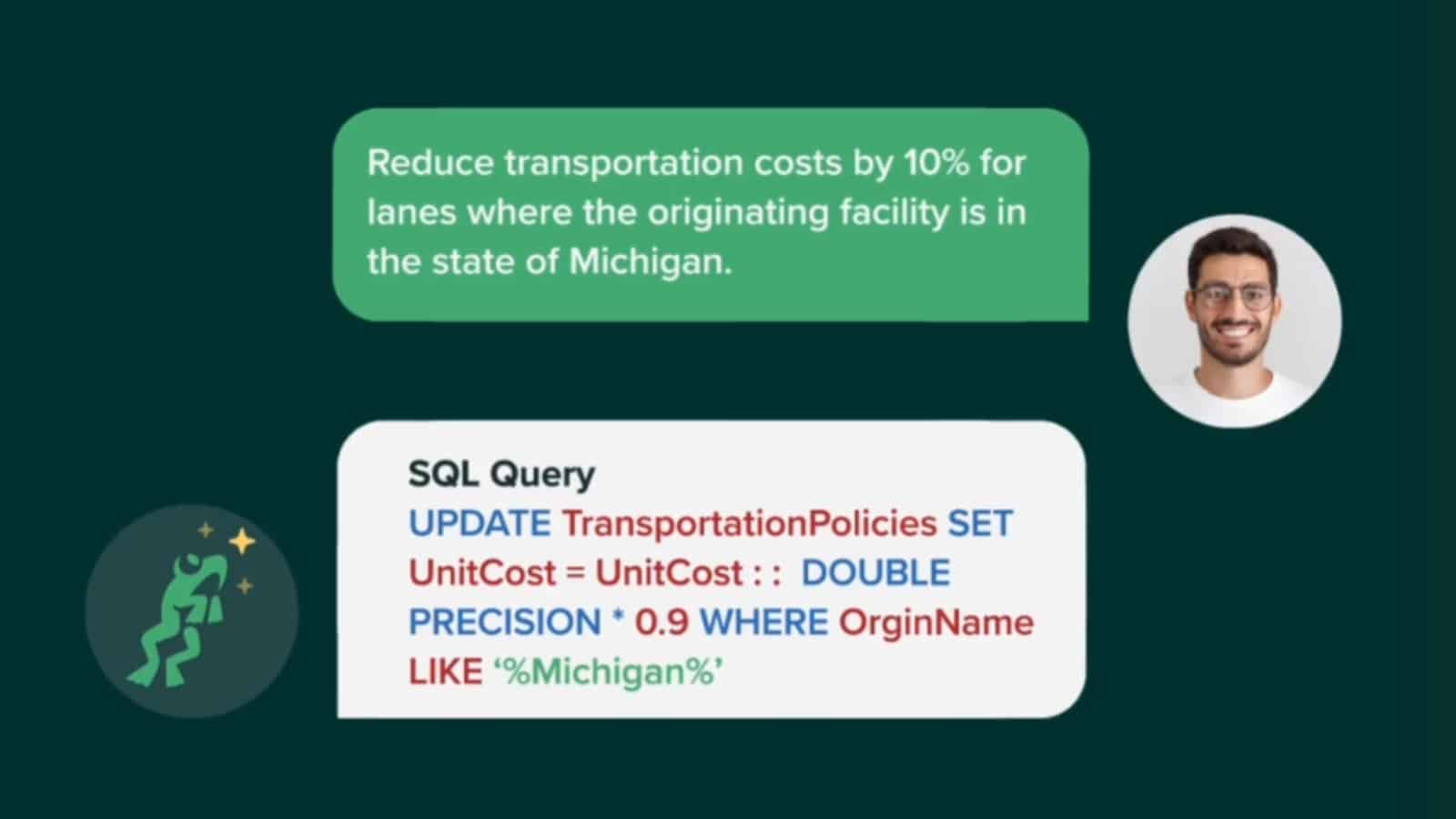

Build a Custom Supply Chain Application in the Optilogic Platform in 3 Steps

It’s very rare that an organization or an individual has the exact same problem to solve as someone else. Often, we’ll find organizations using multiple software tools for specific business functions – and even then the solution isn’t perfect for them. Does this mean we should just settle for less-than-perfect solutions to our problems? Absolutely not. Imagine having the power to build a custom application within the same environment you’re modeling. That’s what we’re about at Optilogic.

What Is Supply Chain Network Design?

Your supply chain design affects every aspect of your organization’s success. You can’t rely on antiquated systems to design supply chains that work in a modern market. Understanding the importance of supply chain network design empowers you to establish smart, resilient supply chains that grow with you and adapt to constant market fluctuations. Here’s what you need to know to get started.

Six Challenges Facing the Logistics Industry

In 2024 logistics and 3PL companies are up against significant challenges that threaten their sustainability. Here are six top challenges facing the logistics industry and how your company can respond to these challenges and proactively position itself for success.

Sustainability in Supply Chain Management: How to Reduce Your Carbon Footprint

Your supply chain design plays a crucial role in your greenhouse gas emission––and reduction. Optimizing your network design empowers you to reduce your carbon footprint without sacrificing quality, productivity, or profits.

Read on to learn how to prioritize sustainability in supply chain management and how Optilogic’s platform can help you create, prioritize, and implement green practices starting now.

7 Key Benefits of Conducting Cost-to-Serve Analysis

Cost-to-serve is a critical practice in supply chain design that helps companies make more informed decisions about how to optimize their operations for maximum efficiency and profitability. A cost-to-serve analysis evaluates the total costs associated with serving a particular customer or segment.

Cost-to-Serve Analysis: A Blueprint for Reaching Higher Profit Margins

Your business might be in the black, but that doesn’t mean all your customers are profitable. Customer segments can vary widely in profitability, which is why cost-to-serve analysis is so important. Understanding the cost distribution for your customer base can help you optimize your supply chain to prioritize the most profitable customers and products.

5 Challenges the Manufacturing Industry Faces in 2023

While challenges are unavoidable, manufacturers can take proactive steps to embrace these challenges as opportunities for growth. This Optilogic blog explores the challenges the manufacturing industry faces in 2023 and how companies can overcome them to win their market.

If You’re Skipping this Important Step, You’re Not Doing Supply Chain Design Right

Due to the COVID-19 pandemic and global events like the war on Ukraine, it wasn’t long before the global supply chain as we knew it had nearly ground to a halt. Today, as we’ve emerged from the worst of it, we’ve learned some crucial lessons about how to design supply chains.

Use this Method to Measure and Quantify Supply Chain Risk

Recently, a series of crises including the COVID-19 pandemic and the obstruction of the Suez Canal had a major impact on the global supply chain, resulting in disruptions such as temporary shortages, delayed deliveries, increased uncertainty, and higher costs for goods and services.

What’s the Difference Between Scenario Modeling and Simulation?

You understand the importance of looking at a myriad of scenarios as part of the supply chain decision-making process, but some of the terms technology vendors use nowadays can be confusing. Good examples are scenario modeling,

what if analysis, and simulation.

What’s the difference between each approach?

Risk Management: The New Essential in Supply Chain Management

You’ve heard over and over again that supply chains must be agile and resilient. Every article, blog post, and podcast stresses the importance of mitigating risk and being able to quickly respond to the disruptions that today’s world continues to produce. It’s clear that Risk Management is a hot topic in supply chain management, but companies are often left scratching their heads on how to stay ahead of future risks instead of just reacting to disruptions that can be seen on the horizon.

How to Use Hyperscaling to Take Supply Chain Models to the Next Level

Many companies are shifting to hyperscale cloud computing for its speed, reduced downtime losses, easier management, and more. Hyperscaling enables users to ask more what-if questions so that they can get more accurate answers, faster. That means more time to actually pinpoint the best strategy that fits your needs, in regards to financials, service, and risk.

Why Retailers have Resorted to Letting Customers Keep their Returned Items: A Failure in Supply Chain Design

While Retailers spend a lot of time building their outbound distribution network, elements of the supply chain like returns, repair, and recycled items are usually not on the radar of the supply chain team. Have you ever been able to return packaging to retailers so they can use the material again? Metrics like contribution to landfill, water resource usage per sku, CO2 contribution per sku, and return cost per sku are usually not top of mind for executives. It’s usually about revenue, new store sales, and margin.

Why We Need to Redefine Supply Chain Design

For the last few years, the team at Optilogic has been busy rethinking the approach to Supply Chain Design. As most of the team has been working in this space for the past decade or two (or more for some of us), we’ve been seeing a need to shift how we model supply chains, what metrics are most important, and what technology to use to successfully deploy supply chain models, simulations and optimizations.

5 Things OptiCon Taught Us About the Future of Supply Chain Design

OptiCon 2022 was definitely one for the books. We discussed topics ranging from how technology innovation was born, sustained and how Supply Chain Design can be re-imagined by combining optimization, simulation, risk management, and cloud hyper-scaling. In case you missed it, here are a few key takeaways from our supply chain thought leadership conference.

The Impact of Fuel and Transportation on Supply Chain Design

A comprehensive Supply Chain Design process that combines optimization, simulation and risk assessment will help you understand the weak-links in your supply chain, and to quickly analyze alternatives when there are profound cost fluctuations or disruptions.

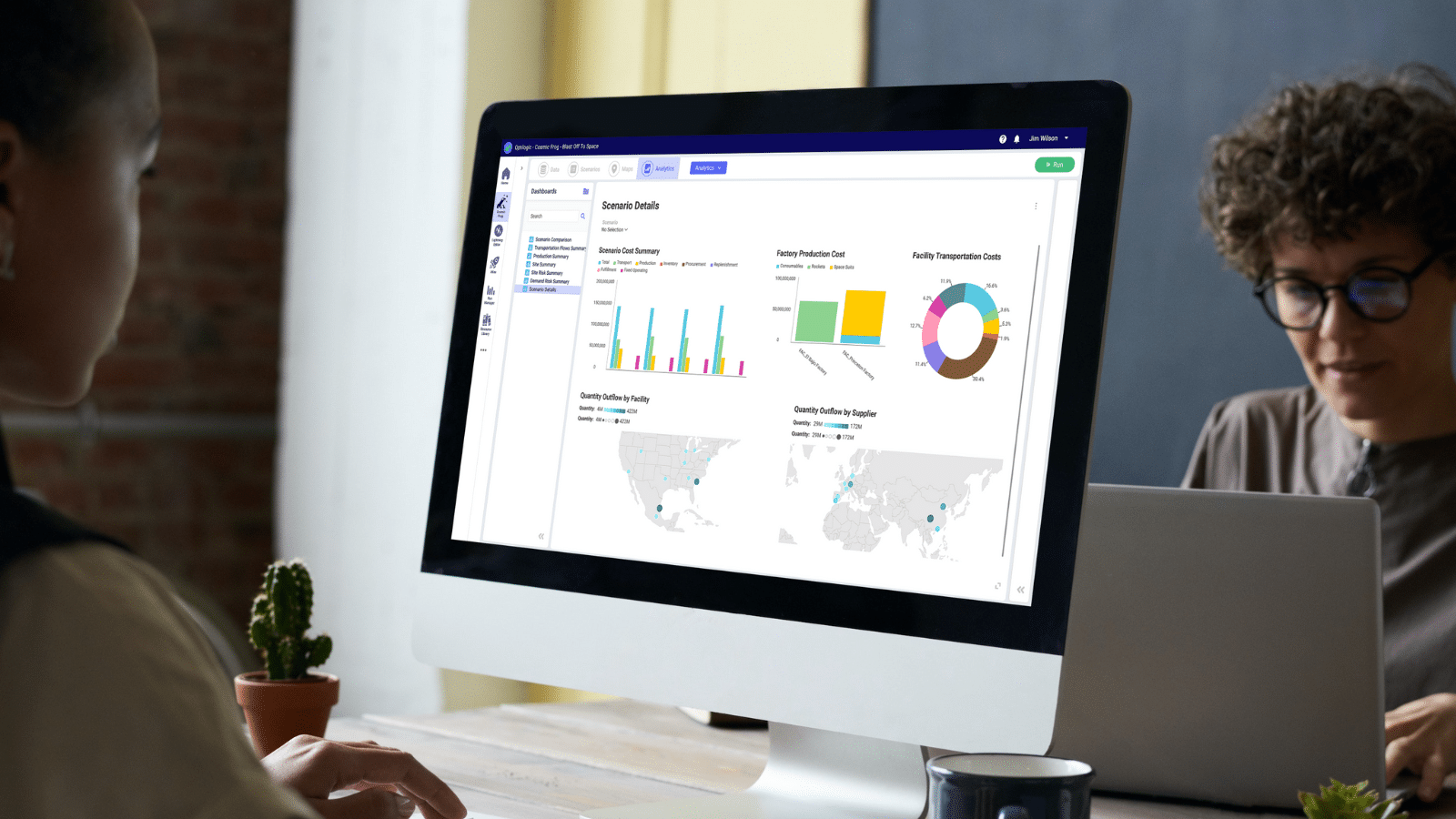

The Convergence of Optimization, Simulation and Risk to Formulate Holistic Supply Chain Strategies

An effective supply chain structure (or architecture) enhances a network’s inherent ability to resist the negative impacts of supply chain disruptions. Because supply chains are generally large and complex, they have posed a challenge to effective planning and decision making, especially when unexpected disruptions occur. This challenge ushered in an era that leaned heavily on computers and complex software to provide decision support capabilities.

Preparing for the Next Big Supply Chain Disruption

Before we can prepare for what’s next, we first need to understand the past. The importance of supply chains pre-dates us by as much as two and a half millennia! Ancient philosophers and tacticians (like Homer and Sun Tzu) wrote about “supplies” and “logistics” and how those impact military campaigns, political aspirations, and other outcomes.

Supply Chain Issues: Chip Shortage Whiplash

By now, we’ve all either heard of or personally experienced the impact of the global chip shortage. But how did our automotive supply chain get to this distressed state? In the simplest of terms, what we’re seeing is the result of strong demand with essentially no supply. This concept is nothing new. In fact, supply chains can be specifically built to withstand shocks to the system. However, the pandemic was something that our supply chain simply wasn’t prepared for, and we’re still feeling its impact, two years later. Here’s what you need to know.

The Benefits of Using Advanced Solvers in Demand Analytics

The day-to-day at Optilogic is constantly changing (and fun), and the way that users implement our software has continued to surprise and inspire us. In a recent project, we built out an application that combined both demand analytics and optimization for short and long term supply chain development.

Bringing Simulation to the Forefront of Supply Chain Design

Recently the Optilogic team has been running into projects that require simulation or a combination of simulations and advanced solving techniques to properly address customer questions about their supply chains. Here are our thoughts on why simulation is becoming more common as a modeling tool than in years past, and how it can make a major impact on any business.

The Use of AI in Supply Chain Design and Analytics

I was listening to Jonathan Wright, Global Managing Partner for Supply Chain Consulting at IBM – discussing with Malcolm Gladwell on his podcast Managing supply chain volatility in the height of the shopping season the latest evolution of supply chain innovation spawned by the global pandemic. And it got me thinking…

Optilogic and Gurobi: A Partnership for the Future of Optimization

We’re thrilled to announce that we have upgraded our platform and have partnered with Gurobi, the world’s fastest mathematical optimization solver on the market. By joining forces with Gurobi, the Optilogic platform now offers a complete end-to-end solution for high-fidelity modeling, optimization, and deployment.

Introducing Professional Services – A Conversation with Mark Outslay

Since the launch of Optilogic, we’re beyond excited to see the influx of new users and what they’ve been able to accomplish in our cloud-based platform. As optimizations continue to get more advanced, we’ve decided to assemble a core team to provide the support users will need to make the most awesome applications. Introducing Mark Outslay, Head of Professional Services at Optilogic. Mark has a 20 year career in supply chain technology and consulting. He works out of Ann Arbor, Michigan.

Introducing The Cloud-Based Modeling Studio: Optilogic

Modelers and engineers from around the world have formulated and coded their optimization and simulation models to solve some of the world’s most complicated problems. Whether you’re modeling the full supply chain of the world’s biggest grocery stores or the performance of a pro athlete, our world is getting better at presenting answers. However, modeling is a lot more nuanced than just knowing what you need to answer. How do we know if we’re asking the right questions? Are we optimizing for the right problem? How confident are we in the results of our optimizations?