Blog

How to Minimize Risk in Santa’s Supply Chain

PUBLISHED ON:

December 21, 2022

Subscribe to Receive the Latest Supply Chain Design Resources

Did you know Santa is about 1,752 years old? St. Nicholas, as he was formerly known, was born around 270 A.D. and has aged surprisingly well, considering all the sweets and the harsh North Pole climate.

But secrets to good skincare aren’t all Santa has learned over the years. He’s also managed to build a solid supply chain strategy to deliver toys around the world. But has Santa considered the supply chain risk factors in his toy delivery strategy?

In anticipation of Christmas, we thought we’d have a bit of fun and build a Cosmic Frog supply chain design model to help Santa distribute gifts in the U.S., considering service (on-time gift delivery) and risk (to ensure reliability).

Santa’s Supply Chain Network Optimization Model

Santa needs to refill his sleigh with presents periodically. The elves distribute toys to storage locations with the items that he needs. So, how many locations should Santa use and where should they be located to minimize the amount of magic needed to get all the children their toys?

We built a model to help Santa optimize his supply chain to distribute presents using the 100 largest cities in the U.S.–one present per person. Santa needs to know:

- How many distribution centers does he need, and where should they be located?

- How can he use risk metrics to improve the resiliency of the network in case of severe weather?

Step 1: Greenfield + Network Optimization Scenarios

First, Santa used Cosmic Frog to identify how many distribution centers (DC) he would need to ensure all “customers” are within 600 miles of a facility.

——> The answer is 7 DCs

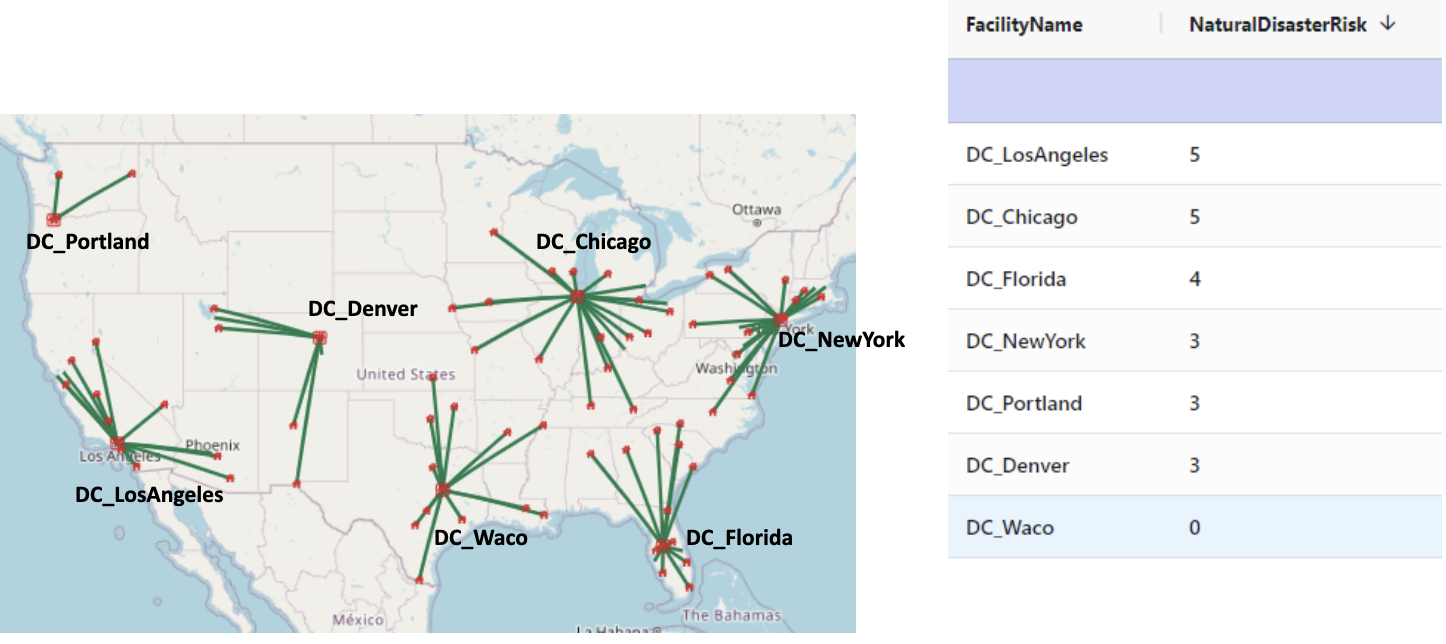

All runs in Cosmic Frog provide the latest risk score using external data sources. As it turns out, two of those DC locations have a relatively high natural disaster risk score of 5 (Chicago and Los Angeles).

Building a supply chain design based on cost alone is unwise in today’s world. Supply chain risk ratings must be considered to ensure that your supply chain can keep running regardless of disruption. You do this by knowing what the risks are that you are taking and planning accordingly. Santa of all people knows he must deliver his presents, come snow or shine!

Step 2: Consider Alternate DCs with Lower Risk

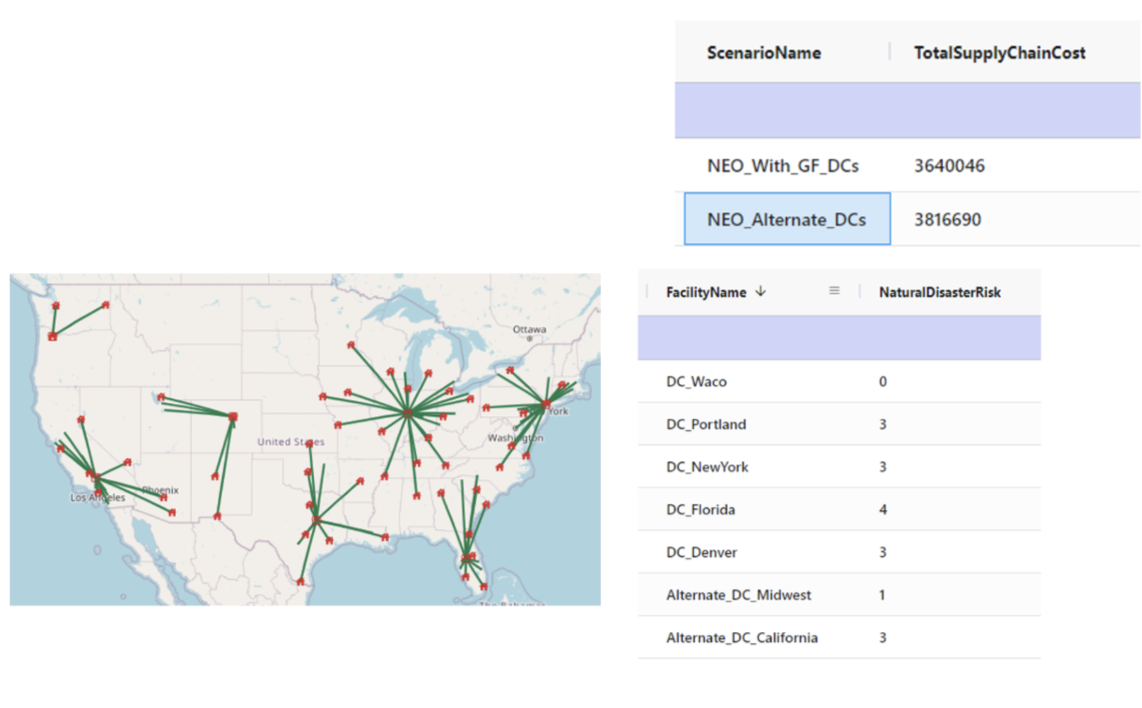

Santa decided to move the location of the two DCs with a high natural disaster risk score more inland. This reduced the risk score from 5 to 1 and 3, respectively.

With lower risk, the cost increases by 4.85%. Santa decided this is a wise investment given all the children counting on him to deliver on Christmas Eve.

How Santa’s Supply Chain Model Is Built

Greenfield Scenario

100 customers, demand equal to city population

Max sourcing distance 600 miles

Objective: Minimize number of DCs

Optimization Scenario #1

Seven facilities from the Greenfield outputs

Objective: minimize cost with $1/mile/unit of demand

Optimization Scenario #2

Five facilities from the Greenfield outputs

Two adjusted facilities to lower natural disaster risk score

Objective: minimize cost with $1/mile/unit of demand

If Santa Can Do It, You Can Too!

There are endless supply chain use cases for Cosmic Frog, and you can get started risk-free today. Sign up for your free account.

Grow Your Knowledge

Supply & Demand Chain Executive Names Mark Outslay of Optilogic as Recipient of 2025 Pros to Know Leaders in Excellence Award

Mark Outslay has fostered the customer success team at Optilogic through an exciting growth stage as they lead onboarding, training, project delivery, and ongoing support for numerous high-profile global companies.

Trump Watch: How New Presidential Energy Policies Will Impact Your Supply Chain Design

Trump signed several executive orders that directly affect U.S. energy policy just on his first day in office. Here’s what supply chain executives need to know about how the Trump 2.0 energy policies will influence supply chain design.