Blog

Six Challenges Facing the Logistics Industry

PUBLISHED ON:

April 24, 2023

Subscribe to Receive the Latest Supply Chain Design Resources

Logistics are the backbone of the commerce industry. When customers purchase a product and expect it to arrive just days later, the logistics and 3PL industry deliver.

As we enter the first quarter of 2024, logistics and 3PL companies come up against significant challenges that threaten their sustainability. This article from Optilogic explores the challenges facing the logistics industry and how your company can respond to these challenges and proactively position itself for success.

1. Persistent Global Labor Shortages

Global labor shortages are the most glaring issue within logistics and the 3PL industry. The persistent labor shortage contributes significantly to the higher costs of goods –– and their production and delivery.

Manufacturers and logistics providers look to automation to resolve the issues caused by the labor shortage. For example, warehousing processes are becoming increasingly automated: regularly, machines now help pick products and send them for packing.

We’re also beginning to see automation in transportation. Europe is already experimenting with automated trucking. Many companies are beginning to experiment with operating trucks without human drivers. The first phases we see are two-truck units wherein the first truck has a driver, and the second truck mimics the driving patterns of the first.

In an era of labor shortages, logistics companies must make the best use of their teams. The Optilogic Cosmic Frog supply chain design solution helps optimize your resources and workforce while respecting the current constraints to get the most out of your available network towards the work/volume requirement.

2. Global Warehousing Shortages Persist

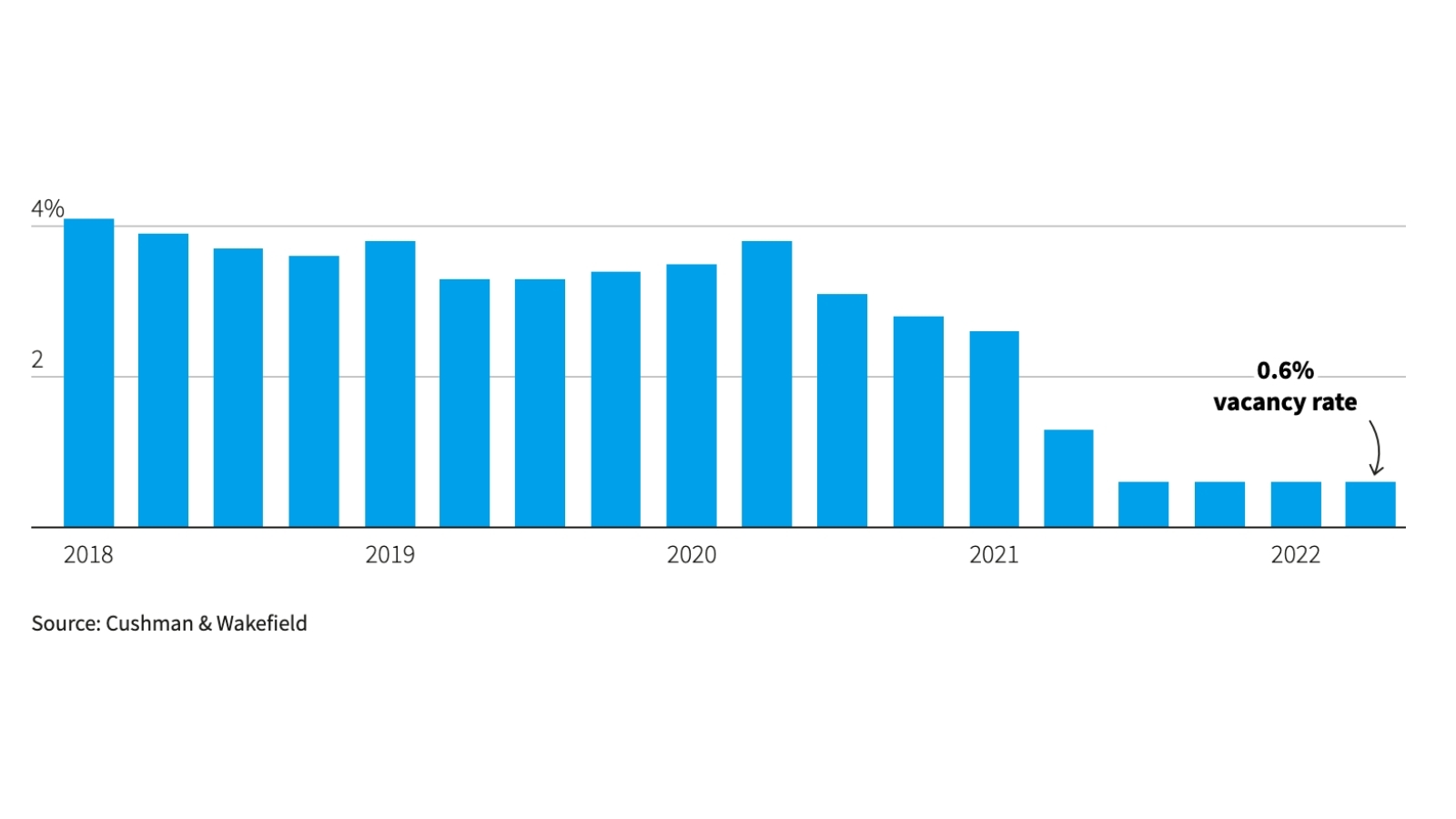

In addition to a lack of labor, warehousing space shortages persist globally. Roughly 30% of warehousing operations are at or above 80% capacity. With the rise of companies using third-party warehouses, fewer warehouses are available, and this space becomes even more coveted.

Southern California’s warehouse market is one of the busiest in the U.S. and is running at record low vacancy.

Amazon’s two-day delivery expectation is a primary culprit in the global space shortage. Warehouses must be located near Amazon’s markets to meet these expectations. Because their demand is increasing daily, there’s very little space for new customers or other peak businesses.

The lack of land near markets presents warehousing challenges as well. Companies need urban fulfillment spaces near their markets, but that land is expensive, if it even exists.

Cosmic Frog can run Intelligent Greenfield analysis to determine the optimal location for your warehousing. Our greenfield models help you see the best site for the best cost, even evaluating the ideal size of your warehouses and how feasible a new space would be for your business now. As e-commerce continues to expand, you need warehousing in proximity to your consumer. Supply chain design software helps you make data-driven decisions that analyze all possible variables to ensure you make the best decisions on your warehousing resources.

3. Continued Industry Consolidations Causing Disruptions

While mergers and acquisitions can streamline production, consolidations also cause disruptions, especially within logistics. Bigger companies acquire smaller companies, making themselves more international. And while this can mean significant growth for companies acquiring smaller companies, it causes disruption and confusion along supply chains.

Mergers are rarely, if ever, executed flawlessly. When they aren’t, supply chain disruptions cause significant resource loss. Companies must find ways to streamline their supply chain mergers to prevent stalls in delivery flows, so they don’t lose profits or suffer drops in customer service levels.

4. Economic Uncertainty

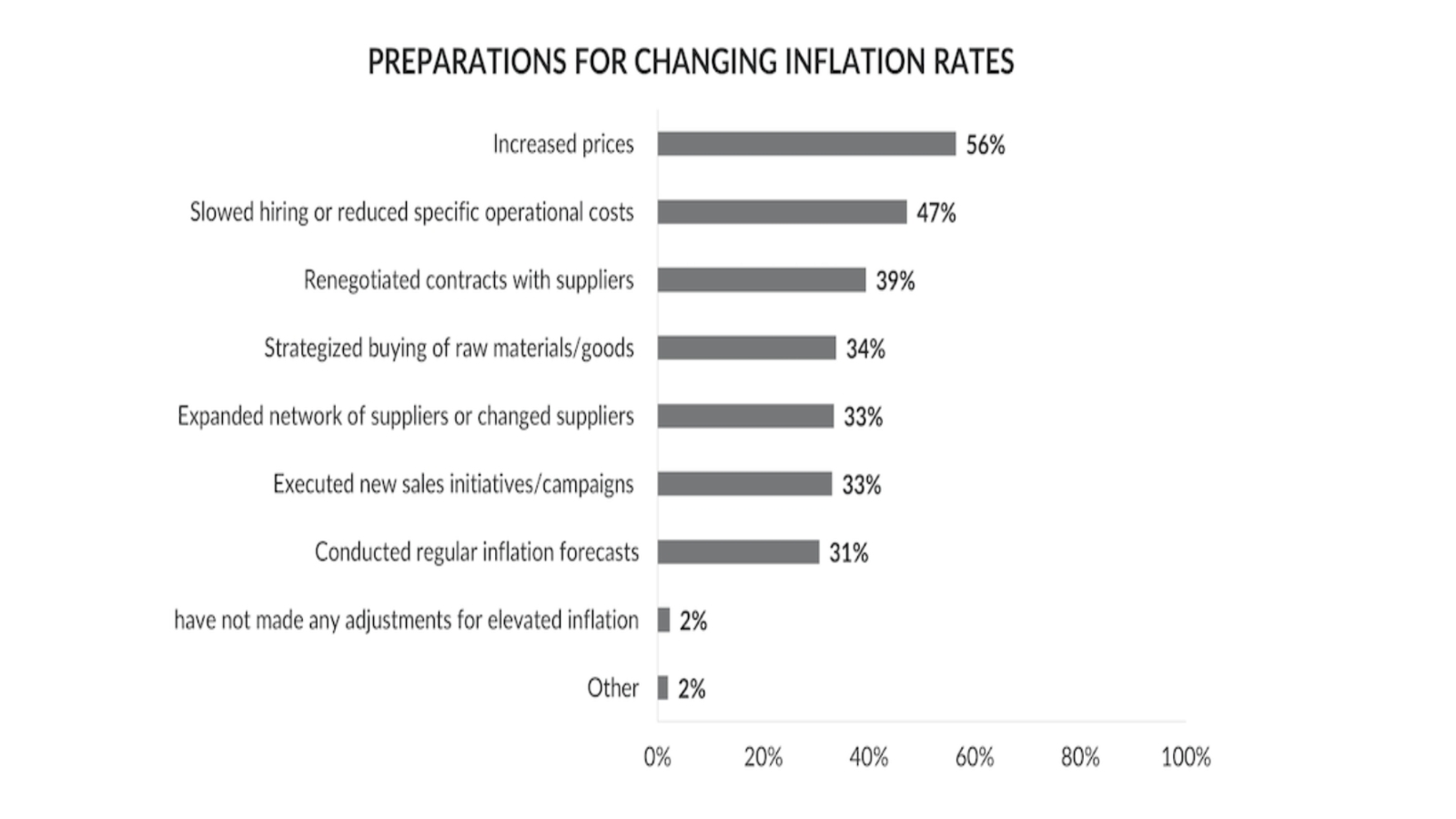

Inflation remains a concern for consumers and producers. And with the threat of recession ever present, companies must strengthen their supply chains to prepare for whatever economic uncertainties come their way.

During a recession, demand levels off, and logistics providers need to make data-driven decisions to position their companies not only to survive but continue to grow. Should you ramp up labor and warehouse space to prepare for the economic bounce back? Or should you take the conservative approach and reduce both?

Price increases are the number one way that businesses have dealt with inflation (56%), followed by slowed hiring or reducing specific operational costs (47%).

Cosmic Frog can model multiple scenarios for your business to help you make those vital decisions and adapt to economic changes, whatever they may be. We model all options using sensitivity analysis so you can better understand how to react to all possibilities. In times of economic uncertainty, supply chain design prepares your business for all possible scenarios.

5. Ability to Service Fulfillment Stagnates

E-commerce continues to expand. Consumer demand and expectations are higher than ever, mainly due to revised customer delivery expectations. Unfortunately, many companies’ ability to service fulfillment cannot keep up with consumer demands.

The 3PL industry directly affects service fulfillment. Warehousing, transportation, and the human element that drives both affect lead time. Companies must find avenues to adapt their logistics processes to reduce the timeframe from inbound delivery to outbound fulfillment to keep up with service fulfillment expectations and maintain a satisfied customer base.

6. Delivery Expectations

Customers now expect expedited delivery with endless product variety––and they want complete data and tracking transparency. Delivery expectations continue to rise while companies wade through disruptions that affect every step of their supply chain. According to Easyship:

- 61% of shoppers want their items delivered within three hours of making an online purchase

- 80% of buyers want same-day shipping

- 17% of online shoppers say they will abandon a brand due to shipping delays

Pre-COVID, lean supply chains were the trend. Post-COVID and other disruptive events (the Suez Canal fiasco and the Long Beach Port congestion crisis) show us that diversified supply chains and awareness of supply chain risks are essential for stability and continued growth.

Companies need to know how much product to hold, where to hold it, and how to prepare for unforeseen supply chain disruptions. Running risk scenarios/simulations through Cosmic Frog helps you make the wisest decisions to prepare for the unknown. We help devise a network and stocking strategy that drives the shortest product delivery while better understanding supply lead times and visualizing the best routes to use for delivery.

How to Create Supply Chain Security in the Logistics Industry

Healthy, diversified, and secure supply chains are essential for logistics companies –– and every other industry –– in 2023 and beyond. Cosmic Frog provides data-driven guidance to create supply chains that you can count on, regardless of the economic storms that come your way.

Cosmic Frog optimizes and simulates activities around the following:

- Network flows

- Volumes

- Capacities

- Logistics moves

- Inventory demand and placements

- Labor

- Asset utilization

- Risk

Given your available supply chain assets, we help you understand how to optimize against demand. Understanding your warehousing space, we create a storage strategy. We can consolidate supply chains upon mergers, running models and evaluating various scenarios to guide your decision-making.

Optilogic helps optimize every element and variable across your supply chain. We empower you to do the things you need to do as efficiently and effectively as possible. As trends come and go and challenges bombard the logistics industry, Optilogic helps you engineer a supply chain designed for resilience no matter what comes your way.