Blog

Key Supply Chain Design Trends Transforming Asia’s Market

PUBLISHED ON:

October 17, 2024

Subscribe to Receive the Latest Supply Chain Design Resources

Minoru Muragi

Co-Founder & CEO at BigM, Inc.

Supply chain executives have been rattled with unpredictable events over the last several years including ongoing trade tensions with China. As a result, many companies are re-evaluating their supply chain network design and diversifying sourcing options to remain resilient despite uncertainty.

Executives today are facing questions such as:

- How do we reduce dependence on China while still maintaining production within Asia? Or should we exit Asia completely and adopt a nearshoring strategy with local production?

- What other countries in Asia could we use to diversify sourcing and production? What risks do these other countries bring?

- How do we evaluate the cost, service, and risk of making changes to supply chain structure and policies? What does “good” look like across these competing metrics?

- How can we assess our supply chain risk to proactively identify and address potential disruptions?

In this blog, we explore the key trends shaping supply chain design in Asia and how executives can assess the trade-offs of alternative sourcing and manufacturing strategies.

Key Trends in Asian Supply Chain Design

Exiting China While Maintaining Asian Production

The notion of exiting China has become a prominent discussion among industry leaders. With rising labor costs, geopolitical tensions, and increasing tariffs, companies are re-evaluating their dependency on Chinese production.

However, completely abandoning the Chinese manufacturing base can be daunting. Businesses are now asking, “How do we reduce dependence on China while maintaining production within Asia?” The answer lies in strategic diversification and gradual transition to other Asian countries that offer lower risks and costs.

For some companies, exiting Asia completely and nearshoring operations may be a viable option.

Diversifying Sourcing and Production in Asia

To mitigate risks associated with a China-centric supply chain, many companies are exploring alternative Asian nations for sourcing and production.

Southeast Asian countries like Vietnam, Thailand, and Malaysia are emerging as viable options due to their growing skilled workforce and favorable economic environments. India’s “Make in India” initiative also positions it as a competitive alternative with its diversified manufacturing base and large labor pool.

Evaluating Cost, Service, and Risk

Before making any changes to the supply chain structure, it is crucial to assess the trade-offs between cost, service, and risk. This evaluation involves analyzing each potential location’s infrastructure, political climate, regulatory environment, and logistical capabilities. The goal is to strike a balance that enhances resilience while optimizing operational costs.

Organizations need to align, from executives to the operational departments – on what metrics define “good” – in terms of cost, service, risk, and sustainability metrics. The cross-departmental alignment is often overlooked when beginning the journey of changing sourcing strategies out of Asia and China in particular.

Proactive Supply Chain Risk Assessment

To stay ahead of disruptions, businesses must adopt proactive risk assessment strategies. This involves leveraging advanced technologies like AI and big data analytics to identify vulnerabilities. By creating a robust system for monitoring geopolitical developments, economic shifts, and environmental challenges, companies can better anticipate and mitigate potential supply chain disruptions.

Building a digital model to measure and quantify potential risks before they occur is critical to disruption-prone supply chains. Supply chain simulation can test the impact on orders and customers impacted, while cost to serve analysis can show the margin impact on products and geographies.

Alternative sourcing, production, and distribution policies that are not in planning systems today can be vetted to understand how best to plan for the top potential disruptions. And sensitivity analysis can reveal how incremental changes to cost, demand, lead-time, and capacity affect the robustness of your supply chain design. These resiliency playbooks could then be developed and at the ready when the real disruption occurs.

Supply Chain Characteristics Across Diverse Asia

Asia is not a monolith; it comprises 48 countries, each with unique characteristics and business practices. Companies must understand these nuances to make informed supply chain design decisions.

For instance, while China offers a skilled labor force and a robust supplier ecosystem, geopolitical uncertainties pose significant risks. Conversely, Southeast Asia’s growth in manufacturing capabilities presents new opportunities for businesses looking to diversify.

Driving Factors in Asian Supply Chain Design

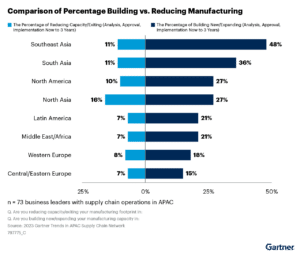

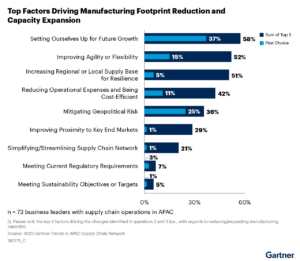

A recent Gartner survey highlighted several critical focuses for business leaders in Asia when it comes to supply chain operations:

- Preparing for Future Growth (58%): Companies are strategizing for long-term growth by investing in scalable and flexible supply chain structures.

- Improving Agility and Flexibility (52%): The ability to quickly adapt to changing market conditions is paramount.

- Boosting Resiliency (51%): Ensuring business continuity despite potential disruptions is a top priority.

The Shift Away from China

There is a marked trend of businesses reducing their capacity or exiting China. This shift is driven by the need to mitigate risks, reduce costs, and enhance resiliency. However, transitioning away from China requires careful planning and consideration of factors like production efficiency, local manufacturing opportunities, and regulatory impacts.

Developing a China Exit Strategy

Formulating an effective exit strategy from China involves several considerations:

- Industry specifics and available regions

- Cost implications and regulatory environments

- Impact on intellectual property and potential disruptions

- Local manufacturing opportunities and geopolitical tensions

Countries like India, Thailand, and Malaysia are becoming increasingly attractive due to their growing workforce skills, political stability, and less regulatory burden compared to China. Enterprises must weigh these factors when evaluating nearshoring strategies to make the most suitable production and sourcing decisions.

Case Studies in Asian Supply Chain Design

Japanese Company’s Drone Logistics Verification Project

Our first case study focuses on a prominent Japanese logistics company, highlighting how sustainability factors are influencing supply chain design in Asia, particularly in Japan. Alongside the growing emphasis on sustainable practices, labor shortages are also posing significant challenges for Japanese businesses.

To optimize their supply chains, the company leveraged Optilogic’s Cosmic Frog supply chain design solution to identify efficient drone delivery routes for specific source-destination pairs. This innovative approach enabled them to assess costs, CO2 emissions, and service metrics effectively. Cosmic Frog facilitated a comparison between drone delivery and traditional trucking logistics, ultimately allowing the company to restructure their delivery systems and achieve a remarkable 25 percent reduction in costs as well as minimizing CO2 and labor.

Global Automotive Leader’s Relocation Case Study

A recent case study showcasing Cosmic Frog’s advanced modeling capabilities involved a global automotive leader assessing the potential relocation of production from China to Europe, resulting in nearly 10 percent cost savings. This strategic move provided immediate financial benefits and opened the door for further savings through diversified supplier options, ultimately leading to an impressive 11.6 percent reduction in costs.

Notably, supplier optimization was initially overlooked but became a key aspect of the supply chain strategy in Cosmic Frog’s recommendations. By leveraging Cosmic Frog’s ability to balance cost, risk, service, and sustainability while analyzing multiple scenarios, the customer was empowered to explore many supply chain optimization opportunities. This approach revealed unexpected avenues for cost savings and strategic improvements, particularly by moving production away from China to Europe, which had not been considered during the initial design evaluation.

Optimizing Supply Chain Design in Asia –– and Everywhere Else You Do Business

Supply Chain Design is crucial for companies worldwide, not just those operating in Asia. In Supply Chain Design decision-making, resiliency, risk, and sustainability are as important as cost, and these factors extend beyond the Asian market. Today, supply chains face constant disruptions from geopolitical risks and increasing concerns about sustainability and CO2 emissions.

Supply chain design has changed, and organizations can no longer assume supply chains from a few years ago make sense today. Optilogic’s cloud native platform enables organizations to build a digital sandbox to test out new ideas to deal with today’s uncertain and volatile world.

Create your free Cosmic Frog account today and start your journey with the most powerful supply chain design tool, ensuring you are ready for any challenges ahead.

BigM – Supply Chain Design Consultant in Tokyo

Minoru Muragi is CEO of BigM, a consulting firm based in Tokyo, specializing in supply chain design, and an Optilogic partner. Our mission is to foster agility, enabling businesses to adapt to the constantly changing external environment and fluctuations, which serve as vital drivers of competitiveness. We offer consulting services to trading companies, logistics providers, manufacturers, and automotive companies, helping them navigate various supply chain challenges. Over time, we’ve observed that many organizations, including those based in the U.S., maintain supply bases in Asia. While each company has unique initiatives and concerns, most—if not all—can be effectively addressed through intelligent supply chain design.