Blog

How to Build a Supply Chain Design Center of Excellence

PUBLISHED ON:

June 1, 2023

Subscribe to Receive the Latest Supply Chain Design Resources

Your supply chain design center of excellence (COE) empowers your organization to hit its targets through balanced, sustainable, resilient supply chain design. Building your COE requires strategic intentionality to create a team that understands your organizational culture, goals, and potential.

Here’s how to build a truly effective supply chain design center of excellence that drives your organization to success.

What Is a Center of Excellence?

In the past, a COE executed supply chain design projects disconnected from the organization. It was considered a strategic decision-making team working around location, mergers and acquisitions, etc.

Now, best-in-class companies think about COEs in a more integrated fashion. It’s no longer a separate entity working independently. Integrating your supply chain design COE empowers you to make short- and long-term decisions that feed your planning, execution, and design systems.

What Does a Supply Chain Design Center of Excellence Do?

A COE digitizes the end-to-end policies, structures, cost, risk, and sustainability metrics to make better decisions and trade-offs around these metrics. High-performing supply chain organizations prioritize certain design aspects that help them succeed and gain a competitive advantage.

Here are some functions of a COE for strategic network design:

- Considers E2E supply chain metrics and identifies target KPIs for your company

- Defines what a “good” supply chain is for your organization based on current and future needs

- Examines how to operationalize your SCD work and how to tie it into existing operations

- Incorporates ESG and sustainability metrics and risk and resiliency (which are as important as cost and service)

- Chooses which technologies to use

- Defines and identifies the teams to build in terms of skill sets

- Builds structural consistency across business units, such as aligning KPIs across the end-to-end supply chain and understanding decision rights across the organization

Getting these things right empowers your COE to perform optimally and positions your organization to meet your shared goals.

Why Is a Center of Excellence Essential for Supply Chain Design?

Disruptions in the supply chain happen more frequently and cost companies more money than ever. Organizations experience an average of 11 disruptions annually, with yearly risk costs averaging $3.85 million. And these numbers aren’t reserved for Fortune 1000 companies; organizations of any size can experience supply chain disruptions.

You must prepare for the future state of your organization, maintaining the ability to quickly build scenarios around events that haven’t yet happened. Your COE acts as a resiliency platform and solves traditional supply chain problems, planning for disruptions at every step.

Many companies consider risk in their operations, but most of the time spent on risk management falls into operations or financial reporting. They aren’t evaluating supply chain strategy and risk resiliency. Unfortunately, that’s where the largest percentage of risk failures leading to significant market decline occurs.

Managing overall supply chain design and strategy as it relates to risk is a central focus of your CEO. Without a supply chain design CEO evaluating your risk, you leave your organization vulnerable to preventable disruptions that can devastate your business.

Industry 4.0 and Supply Chain Design

In the past, many companies utilized supply chain design COEs, but lacked a living scorecard helping them understand how the supply chain was performing. Cost minimization was the top priority.

Today you must consider other metrics to ensure you’re performing optimally with the best supply chain for your organization at any given moment. It’s continuous optimization that empowers you to take hold of your market share.

Industry 4.0 is the next phase of the digitization of manufacturing. Creating digital models of your organization allows you to run limitless simulations that model transaction-level details of a supply chain. It operates from a cloud-native approach, solving beyond optimization. It’s about tying into the business leadership and operations, understanding the KPIs for what defines a good supply chain.

Digital models provide high-level insights concerning future states, including data regarding service level and production policies. You can run your models on an ongoing basis offline from planning and execution but utilize the same data you’re using to run your business.

That wasn’t the case just a few years ago. Now, cloud-based platforms have made this possible through scale, and the analytics around machine learning can complement optimization and simulation in terms of building a COE and understanding what’s going on across the end-to-end supply chain.

How to Think about Building a COE

Building your COE is less about a physical center of excellence and more about supporting an organization with supply chain design. Your COE coordinates projects and initiatives that help drive the business, the metrics you prioritize, and how you value those metrics.

Below we outline the fundamentals of a COE and the characteristics to prioritize when creating your teams.

1. Design Converges with Planning

Supply chain design COE designs flows and policies that can be tested for the future state of your business. Future states represent planning and execution policies that can be done within your supply chain design COE, including a new supplier you’re considering, a new port you’re shipping to, a new demand you are trying to meet, inventory and production policies, and more.

Any successful organization must be proactive about measuring itself and working with a COE to make organizational decisions that drive the business toward its goals. The COE must be a sustainable piece of the company and be recognized from the top down.

2. Cultivating a COE Ecosystem

Understanding metrics and skills needed for projects and how they’re connected will often require external analytics, change management, data integration, or business workflow experts.

How do you get your organization to think in these terms? The COE does not operate independently to accomplish these things. Your COE might have specific skill sets that are part of their organization, but often they’re connected to the business. Thorough integration and cohesion are required for a successful, sustainable COE that helps your business thrive.

3. Attributes of Mature and Resilient COE Organizations

Your COE drives many elements of your organization’s supply chain design decision-making. The following attributes of mature, resilient organizations should be considered when building and evaluating existing COEs.

Process

Risk-resilient organizations communicate risk information clearly, including policies, procedures, practices, and thresholds. They can perform “what if” scenarios and change analysis.

Organization

Roles and responsibilities are designed and created to execute risk initiatives. A clear path of accountability exists for risk management within the overall governance framework.

Knowledge

Mature organizations integrate risk information into their core decision-making procedures. They can drill down to successive levels of detail from summary risk information.

Technology

Without the right tools, it’s impossible to optimize for risk. Organizations must provide their COEs with the right technology, including query and reporting tools, heat maps, dashboards, scorecards, ERM systems, and event management software.

Performance

Lastly, these organizations integrate and align risk with overarching corporate goals.

Optilogic Can Support Your COE for Supply Chain Design

The concept of a COE is simple enough to grasp, but getting started can be intimidating, especially as various departments shoulder incredible responsibility to keep your organization moving forward.

Creating your COE begins with identifying a key problem that needs solving, then working with the organization to solve it, highlighting how a COE can help in terms of the technology and skills required.

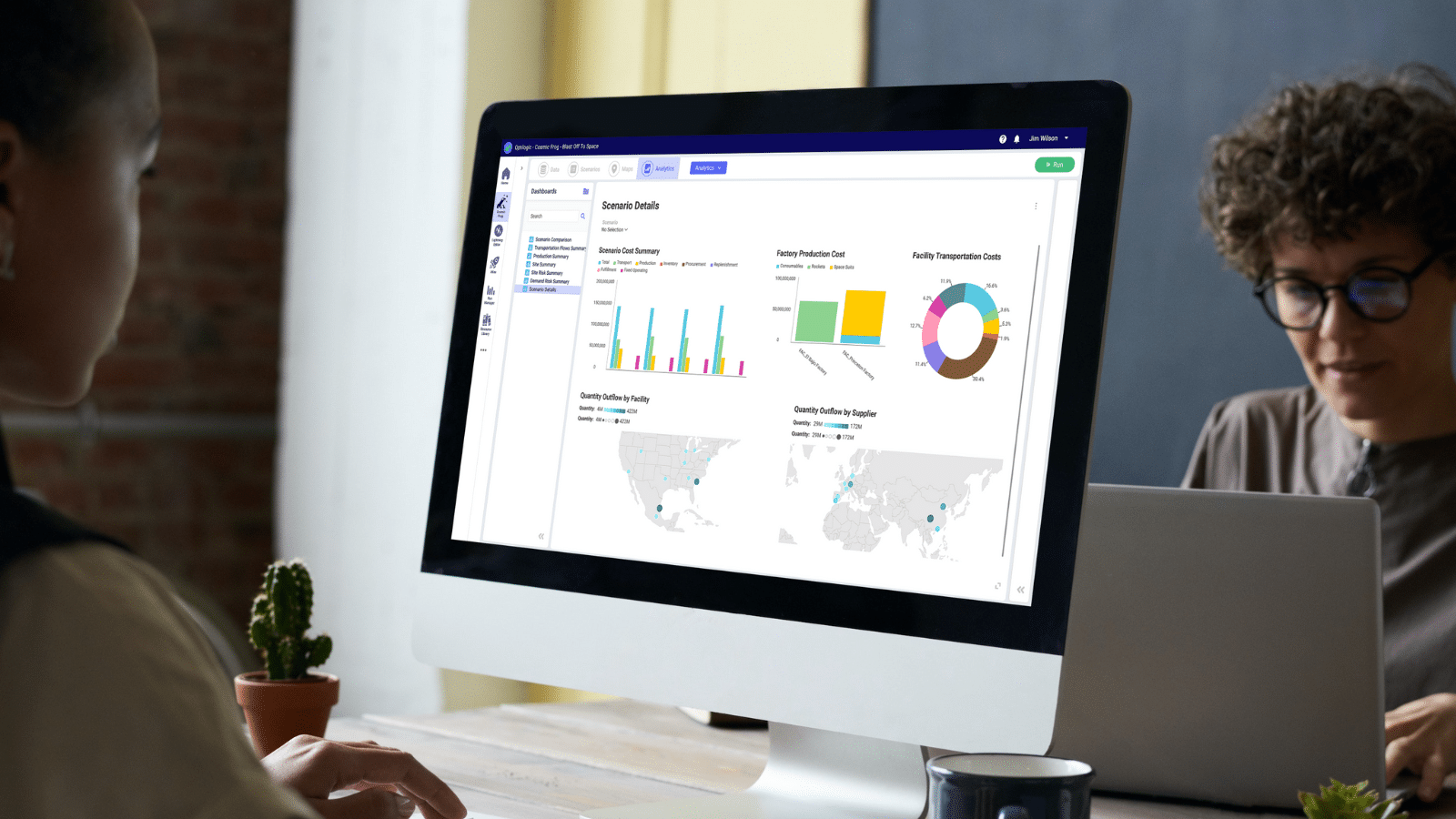

The Optilogic Cosmic Frog supply chain network design solution enables COEs to make the best decisions for their organizations. Our platform supports COEs because of our cloud-native structure that delivers the ability to scale, share, and collaborate across your company. Cosmic Frog is the only supply chain design platform that balances financials, service, and risk in a SaaS-based environment.

Create your free Cosmic Frog account today to empower your COE with the tools and technology required to guide your organization forward.

Grow Your Knowledge

Supply & Demand Chain Executive Names Mark Outslay of Optilogic as Recipient of 2025 Pros to Know Leaders in Excellence Award

Mark Outslay has fostered the customer success team at Optilogic through an exciting growth stage as they lead onboarding, training, project delivery, and ongoing support for numerous high-profile global companies.

Trump Watch: How New Presidential Energy Policies Will Impact Your Supply Chain Design

Trump signed several executive orders that directly affect U.S. energy policy just on his first day in office. Here’s what supply chain executives need to know about how the Trump 2.0 energy policies will influence supply chain design.