Blog

Your 5 Scariest Supply Chain Design Problems

PUBLISHED ON:

October 31, 2023

Subscribe to Receive the Latest Supply Chain Design Resources

It’s that spooky time of year again…werewolves, witches, goblins…and frightening supply chains?

That’s right, cavities aren’t the only thing haunting grown-up nightmares this time of year. In anticipation of the holiday season and a new year right around the corner, scary supply chain problems are keeping practitioners up at night.

Don’t be afraid…read on to uncover five of the scariest supply chain design problems and how you can solve them with the Cosmic Frog supply chain design solution to sleep peacefully again.

Bwa ha ha ha!

1. Supplier Shut-downs

When thinking about supply chain fears, supplier failure is certainly near the top. What happens when a supplier goes down for a week? For six months? Which of your suppliers are risky? What should you do in the event of supplier failure?

In the past, network design solutions ignored risk when balancing trade-offs of facility and supplier decisions. Today it’s a snap to answer supply chain what-if questions like these considering cost, service, and risk with Cosmic Frog.

To measure and quantify these risk scenarios, no extra work is needed! Simply run your Cosmic Frog supply chain design model and your Opti-Risk score is calculated automatically. Next, identify the scenarios that minimize risk while maintaining profitability and service. Then, proactively create contingency plans to prepare for any disruption.

2. Figuring out the Right Number and Locations for Facilities

According to Gartner, 74% of supply chain leaders made changes to the size and number of facility locations in the past two years.

Planning for new facilities or market expansion can be a scary challenge on its own, but reducing transportation expenses and emissions without sacrificing customer service is even trickier.

The questions abound:

- How many distribution centers do we need?

- Where should our facilities be?

- How do we minimize transportation spend without sacrificing service?

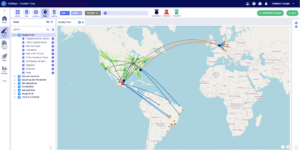

Greenfield analysis (GFA) helps determine optimal locations for production facilities and distribution centers. It streamlines supply chain network design by identifying a central location within easy reach of high-yield customers.

With Cosmic Frog Intelligent Greenfield analysis, all you need to map out your ideal production facilities, distribution centers, and warehouse locations is customer location and customer demand–Cosmic Frog Intelligent Greenfield analysis does the rest.

And did we mention it’s scary fast? Intelligent Greenfield is 80% faster than other supply chain design solutions.

3. Inventory Service Failures

Avoiding inventory service failure is essential in hyper-competitive service environments. But when supply chain uncertainty is the new norm, it can be a freaky problem.

Most practitioners are accustomed to inventory optimization that uses abstracted, aggregated demand, lead times, and capacity. But this leads to inaccurate and unactionable results: overstocks, service failures, and lost profit.

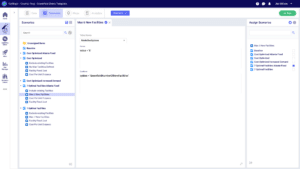

You can use Cosmic Frog’s combined optimization and simulation approach to answer inventory questions like these to avoid service failures:

- Where should stocking locations be located throughout the network?

- What should stock levels be at each location?

- Which policies should be used at each stocking point to decide when to reorder inventory and how much to reorder?

Because Cosmic Frog uses simulation optimization models at the order/SKU level and allows users to explore the full trade-off curve between service and cost, you can easily pinpoint the bullseye.

See how to avoid inventory frights with Cosmic Frog

4. Evaluating Nearshoring Strategies

Nearshoring analysis is a hot topic and only getting more critical with growing concerns about China supply chain issues. In fact, 95% of respondents in a recent survey were evaluating or executing changes to their China sourcing and manufacturing strategy.

The risk to doing business in China has gone up, and the cost advantage has been shrinking for quite a while. The reshoring problem is not for the faint of heart: It’s unpredictable and can involve significant changes to supply chain structure and design.

While the nearshoring problem may be scary, supply chain design is the perfect complement to tame it. Supply chain design is all about a balancing act of the service that your network provides, financial performance, and the risk inherent in the network. With Cosmic Frog, you can model your supply chain and see if nearshoring is worth the change—with no guessing or regret later.

Listen to Optilogic CEO Don Hicks talk about nearshoring decisions

5. Wasting Resources on Unprofitable Customers

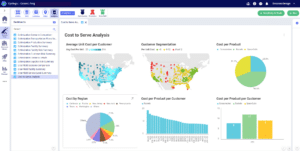

Your customer segments can vary widely in profitability. Understanding the cost distribution for your customer base can help you optimize your supply chain to prioritize the most profitable customers and products. If you don’t know which are your most profitable—and unprofitable—customers, well, that’s pretty scary.

Cost-to-serve supply chain analysis reveals how the costs associated with certain customers and product lines vary. Supply chain managers can use this data to inform decisions about pricing, product mix, and distribution strategy.

Cosmic Frog doesn’t just calculate the landed cost for end customers. It calculates and reports landing costs for every intermediate node, including suppliers, plants, and distribution channels. Users get a clear picture of landing costs from the product’s origin to the moment it reaches the customer, and every step in-between.

Best of all, cost-to-serve runs automatically in Cosmic Frog, meaning you can understand the cost to fulfill demand and replenish facilities across the entire supply chain—on every scenario.

If You’re in a Rut, Don’t be Afraid to Change Your Situation

If you’re doing the best you can each day but unable to move the needle on KPIs, perhaps it’s time to change your situation.

With supply chain design, you can deal yourself a new hand. Contact us or watch a demo of Cosmic Frog to see how you can push the efficiency frontier past what your supply chain planning software can do.

Turns out things aren’t that scary at all.

Grow Your Knowledge

7 Expert Tips for Building a Sustainable Supply Chain Design Organization

A successful, profitable, sustainable supply chain starts within your organization. Developing internal competency for supply chain design and network optimization capabilities is at the core of not only supply chain success but also the success of your entire company. At the OptiCon 2024 event, Kerry Rosenhagen, managing director at NTT Data Supply Chain Consulting co-led a session explaining the foundations of effective supply chain design.