Blog

5 Challenges the Manufacturing Industry Faces in 2023

PUBLISHED ON:

March 28, 2023

Subscribe to Receive the Latest Supply Chain Design Resources

Manufacturing is uniquely positioned in 2023. Businesses see unlimited potential for growth thanks to an ever-expanding digital shelf and increased consumer demand. But the industry faces many challenges that, if unmet, can cause breakdowns in companies that yield detrimental results.

While challenges are unavoidable, manufacturers can take proactive steps to embrace these challenges as opportunities for growth. This Optilogic blog explores the challenges the manufacturing industry faces in 2023 and how companies can overcome them to win their market.

1. Labor Shortages

The manufacturing industry is experiencing a massive shortage of skilled laborers. In recent decades, there’s been a significant emphasis on students pursuing a college education and advanced degrees. The millennial generation and younger have been pushed into technical roles and encouraged to go the business route, leaving a gap in skilled laborer roles.

In addition to the shortage of skilled workers is the issue of facility placement. As plants and manufacturers explore new locations, often called Greenfield analysis, companies must evaluate the cost efficacy of manufacturing locations. These facilities are either not positioned in areas with strong pockets of labor, or other industry players have already invested into new facilities in the same region. Both result in a lack of workers to fill positions. Often, manufacturers are investing into regions that are growing hubs for Tier-1 or Tier-2 suppliers to their industry and competition for talent becomes fierce.

As manufacturers address the challenges posed by labor shortages, they must proactively address the root causes and make strategic supply chain decisions that help them recruit and maintain the valuable talent they need.

According to Tony Schmitz, Professor of Mechanical, Aerospace and Biomedical Engineering, University of Tennessee, “To grow the skilled manufacturing force, the creation of a more robust K-12 education system that emphasizes STEM subjects – science, technology, engineering and math – while simultaneously providing vocational programs and apprenticeships for all students is important.”

However, US students continue to fall behind in science and math performance, further threatening a strong domestic manufacturing workforce.

2. Ongoing Supply Chain Uncertainty

Supply chain became a buzzword as COVID changed everything about how we operate, both in the business world and as individuals within communities. When COVID caused global shutdowns, supply chains quickly crumbled, leaving a damaged manufacturing industry in its wake.

When supply chains fractured, manufacturers could not get parts from their suppliers, from plastic bags to powdered cheese to computer chips. That bullwhip effect was rippling up and down the supply chain, and it wasn’t felt only in vital materials. Equipment supply was deeply affected too. Facilities did not have trucks or tractors to move supplies. Products were stuck in port.

Every aspect of manufacturing, from production to delivery, was and is still affected by supply chain vitality. The effects of COVID highlighted all the weak links within the supply chain.

Unfortunately, the industry hasn’t fixed all those intertwined weaknesses. During COVID, companies scrambled to get their supply moving as fast as possible, by switching from ocean freight to air freight transport, for example. However, supply chains are still vulnerable structurally. Companies have started to build up supply chain risk teams, it will take years to shore up resiliency.

3. Inflation

Everyone feels inflation. As manufacturers try to recover from COVID and resulting shortages, input and labor costs continue to rise. There’s no solution to balancing the cost of inputs, like transportation and warehousing. Manufacturers take that cost to the consumer.

Inflation affects every aspect of manufacturing. Manufacturers are trying to maintain an appropriate profit margin and profitability and move those profits into creating a sustainable supply chain while getting goods to the consumer. It’s a tricky balance for many companies.

Consumers are unhappy with the cost of goods, but there’s no immediate remedy. To survive in this economic climate, manufacturers must continue to deliver on customer expectations on pricing, quality, timelines, and service while maintaining profitability.

4. Technology in Manufacturing

Manufacturers rely heavily on ERP systems to operate smoothly as supply chains become increasingly digital.

However, within the manufacturing industry, most ERP systems need to be updated. The same systems implemented 40 years ago are still utilized today. They’re desktop based and difficult to integrate across multiple systems, suppliers and global trade partners. These systems were developed when manufacturing wasn’t about global supply chain management.

The industry has fallen severely behind in technology adoption, specifically with ERP systems and the inability to link into global supply chains. This results in disconnected data links and siloed visibility into critical supply chain data.

As specialized tech companies like Optilogic address challenges facing the manufacturing industry, the expectation for data management grows and manufacturing companies must invest.

When companies implement new software systems, like an updated ERP, it’s an organization-wide endeavor that requires buy-in from all parties. Unfortunately, during these ERP projects, people with data and supply chain skills are kept busy for long periods of time which sometimes leaves significant gaps in capabilities and resources for crucial supply chain redesign projects.

Everyone in the company––from the CEO to supply chain analyst is reliant on access to granular data points for improved supply chain decision-making.

Implementing new technology systems is a cross-functional, cross-departmental switch; it’s a personnel commitment; it’s a massive undertaking. And it’s creating challenges across the manufacturing industry.

5. Social Pressure

Social pressures have more influence than ever on the manufacturing industry. And with these influences comes the constant challenge of meeting or exceeding consumer expectations. Consumers demand transparency and sustainability from manufacturers. We explore these two unique pressures below.

Transparency

Thanks to Amazon, we know when our order has been received, when it’s in packaging, when it’s hit the truck, how many stops away it is, and when it’s been delivered. From the moment customers place an order, they can access product and manufacturing data.

Customers want to know where every product is at all times: when it was produced, what line it was produced on, etc. What was an in-house practice from Amazon has shaped how manufacturing companies think about data transparency.

Manufacturing transparency requires manufacturers to record, maintain, and share a high volume of data with consumers. And everyone along the supply chain has access to that data. That’s where data security within the supply chain becomes essential.

The demand for transparency along the supply chain is a demand for data security.

Sustainability

Sustainability questions, concerns, and issues abound within the manufacturing industry.

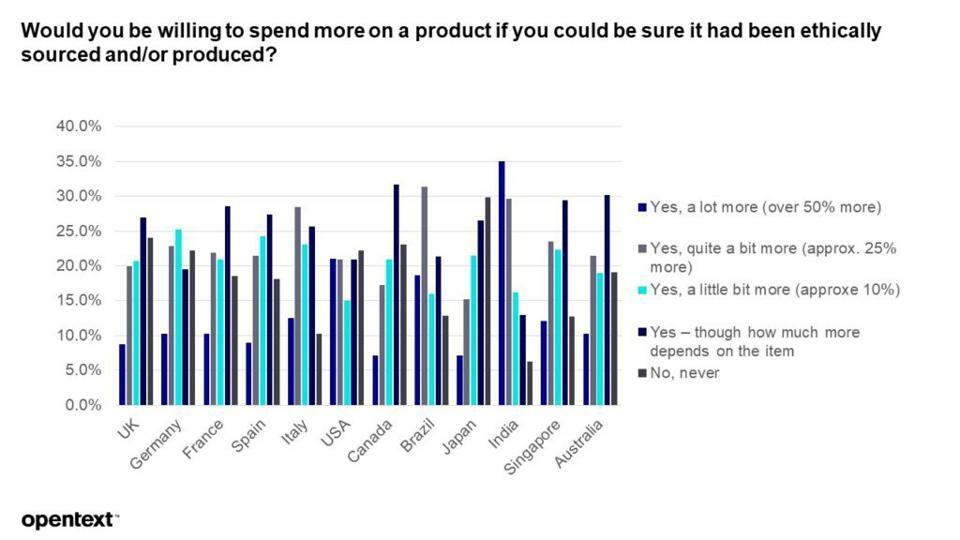

Nearly 90% of Gen X consumers said that they would be willing to spend an extra 10% or more for sustainable products, compared to just over 34% two years ago (First Insight). Furthermore, according to Gartner, 87% of business leaders expect to increase their organization’s investments in sustainability over the next two years.

Consumers want, expect, and demand sustainability from manufacturers and their supply chains. Buyers ask manufacturers:

- What are your sustainability practices?

- What certificates do you hold?

- How are you giving back socially and environmentally?

- What’s your carbon footprint?

But because many companies within manufacturing, don’t have insights into that information, these questions go unanswered.

Modern supply chain design technology considers all supply chain components—labor, location, inflation, technology, social pressures and more––to design your supply chain to delight customers, increase profitability, and produce goods with environmental responsibility.

Overcoming Manufacturing Challenges with Optilogic

Optilogic prioritizes supply chain design that impacts you today, two years, and 10 years down the road. It looks at customer demand at its location, your supply, where you produce your goods, and the origin of your vitals or raw materials. Using that information, Optilogic Cosmic Frog supply chain design software designs an array of future supply chain designs and allows you to trade off service, financial performance, and systemic risk to find the design that meets your needs.

Supply chains drive manufacturing success. As you build strategies to overcome the challenges 2023 will bring, you need supply chain design and expertise that positions your company to win.

We create realistic, sustainable, functional solutions for manufacturing companies like yours. Ready to get started? Create your free account and contact us for help along the way.

Grow Your Knowledge

7 Expert Tips for Building a Sustainable Supply Chain Design Organization

A successful, profitable, sustainable supply chain starts within your organization. Developing internal competency for supply chain design and network optimization capabilities is at the core of not only supply chain success but also the success of your entire company. At the OptiCon 2024 event, Kerry Rosenhagen, managing director at NTT Data Supply Chain Consulting co-led a session explaining the foundations of effective supply chain design.