Adding Sourcing Policies via the Sourcing Tables (Simulation)

In a supply chain model, sourcing policies describe how network components create and order necessary materials. In Cosmic Frog, sourcing rules & policies appear in two different table categories:

How to add sourcing rules via the Model Elements tables is described in this Help Center Article.

These are the tables in the Sourcing category where sourcing policies can be defined.

In this section, we will discuss how to use these Sourcing policy tables to incorporate real-world behavior. In the sourcing policy tables we define 4 different types of sourcing relationships:

- Customer fulfillment policies

- Replenishment policies

- Procurement policies

- Production policies

First we will discuss the options user has for the simulation policy logic used in these 4 tables and the last section covers the other simulation specific fields that can be found on these sourcing policies tables.

Sourcing Policies Tables and their Simulation Policy Options

Customer fulfillment policies

Customer fulfillment policies describe which supply chain elements fulfill customer demand. For a Throg (Simulation) run, there are 3 different policy types that we can select in the “Simulation Policy” column:

- By preference

- Single source

- Allocation

If “By Preference” is selected, we can provide a ranking describing which sites we want to serve customers for different products. We can describe our preference using the “Simulation Policy Value” column.

In the following example we are describing how to serve customer CZ_CA’s demand. For Product_1, we prefer that demand is fulfilled by DC_AZ. If that is not possible, then we prefer DC_IL to fulfill demand. We can provide rankings for each customer and product combination.

Under this policy, the model will source material from the highest ranked site that can completely fill an order. If no sites can completely fill an order, and if partial fulfillment is allowed, the model will partially fill orders from multiple sources in order of their preference.

If “Single Source” is selected, the customer must receive the given product from 1 specific source, 1 of the 3 DCs in this example.

The “Allocation” policy is similar to the “By Preference” policy, in that it sources from sites in order of a preference ranking. The “Allocation” policy, however, does not look to see whether any sites can completely fill an order before doing partial fulfillment. Instead, it will source as much as possible from source 1, followed by source 2, etc. Note that the “Allocation” and “By Preference” policies will only be distinct if partial fulfillment is allowed for the customer/product combination.

Example By Preference vs Allocation

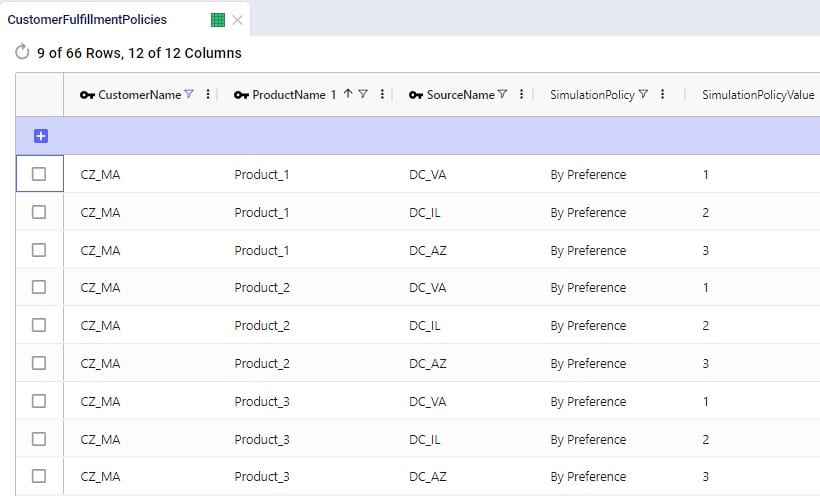

Consider the following example, customer CZ_MA can source the 3 products it puts orders in for from 3 DCs using the By Preference simulation policy. For each product the order of preference is set the same: DC_VA is the top choice, then DC_IL, and DC_AZ is the third (last) choice. Also note that in the Customers table, CZ_MA has been configured so that it is allowed to partially fill orders and line items for this customer.

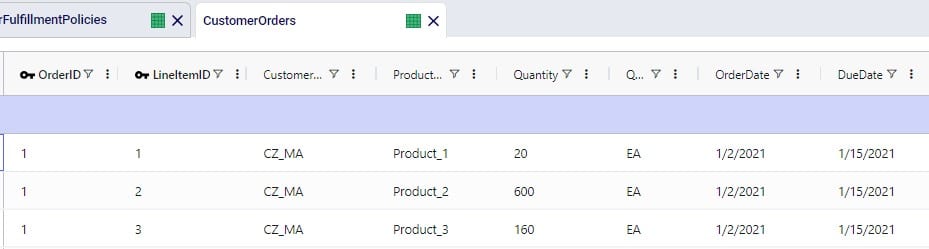

The first order of the simulation is one that CZ_MA places (screenshot from the Customer Orders table), it orders 20 units of Product_1, 600 units of Product_2, and 160 units of Product_3:

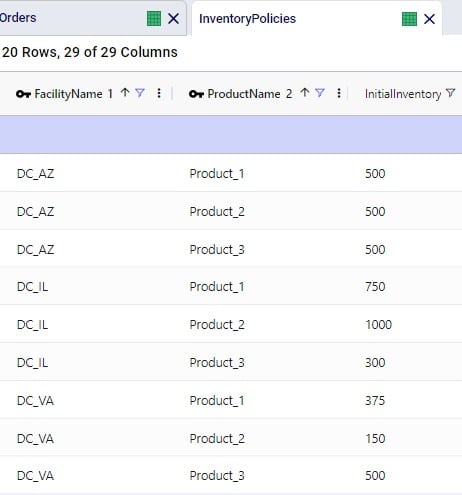

The inventory at the DCs for the products at the time this orders comes in is the same as the initial inventory as this customer order is the first event of the simulation:

When the simulation policy is set to By Preference, we will look to fill the entire order from the highest priority source possible. The first choice is DC_VA, so we check its inventory: it has enough inventory to fill the 20 units of Product_1 (375 units in stock) and the 160 units of Product_3 (500 units in stock), but not enough to fill the 600 units of product_2 (150 units in stock). Since the By Preference policy prefers to single source, it looks at the next priority source, DC_IL. DC_IL does have enough inventory to fulfill the whole order as it has 750 units of Product_1, 1000 units of Product_2, and 300 units of Product_3 in stock.

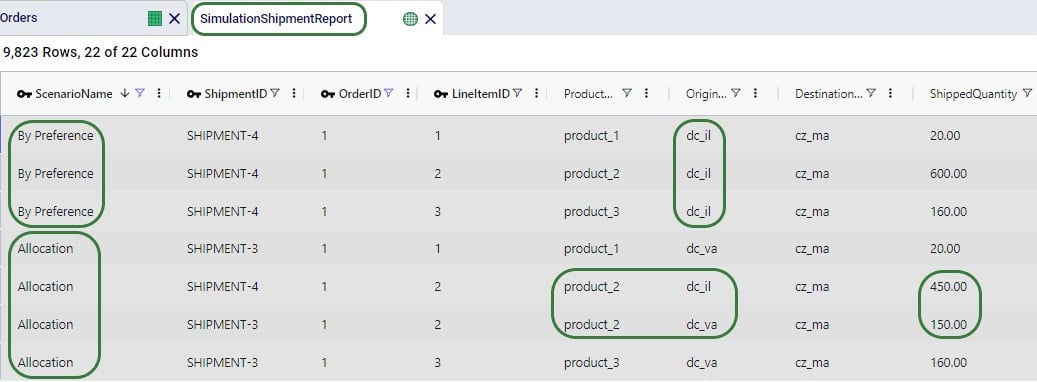

Now, if we change all the By Preference simulation policies to Allocation via a scenario and run this scenario, the outcomes are different. In this case, as many units as possible are sourced from the first choice DC, DC_VA in this case. This means sourcing 20 units of Product_1, 150 units of Product_2 (all that are in stock), and 160 units of Product_3 from DC_VA. Then next, we look at the second choice source, DC_IL, to see if we can fill the rest of the order that DC_VA cannot fill: the 450 units left of Product_1, which DC_IL does have enough inventory to fill. These differences in sourcing decisions for these 2 scenarios can for example be seen in the Simulation Shipment Report output table:

Replenishment policies

Replenishment policies describe how internal (i.e. non-customer) supply chain elements source material from other internal sources. For example, they might describe how a distribution center gets material from a manufacturing site. They are analogous to customer fulfillment policies, except instead of requiring a customer name, they require a facility name.

Procurement policies

Procurement policies describe how internal (i.e. non-customer) supply chain elements source material from external suppliers. They are analogous to replenishment policies, except instead of using internal sources (e.g. manufacturing sites), they use external suppliers in the Source Name field.

Production policies

Production policies allow us to describe how material is generated within our supply chain.

There are 4 simulation policies regarding production:

- Make by demand – triggers production events based on sourcing policies that pull from the site.

- Make by schedule – the production scheduled is defined in the Production Orders table, where quantities, and order & due dates can be specified. A production pattern can be specified in the Production Order Profiles table.

- Make by demand and schedule – combines the previous 2 policies.

- Continuous production – continuously triggers production orders of the amount specified in the “Lot Size” field as soon as the production of the previous lot is completed.

Other Fields on the Sourcing Policies Tables

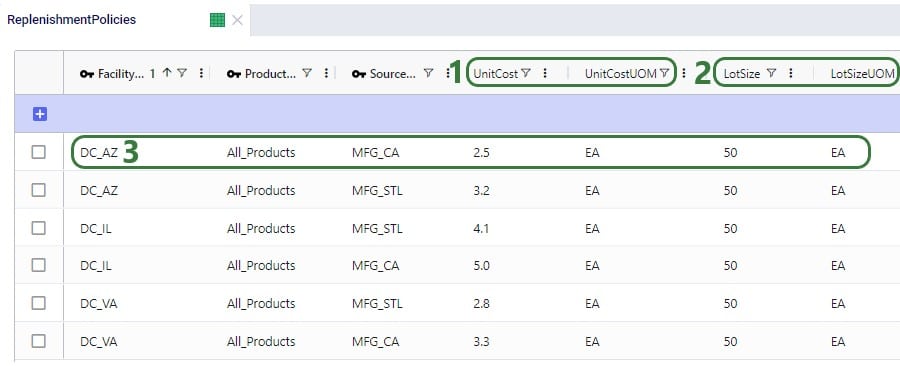

Besides setting the Simulation Policy on each of these Sourcing Policies tables, each has several other fields that the Throg Simulation engine uses as well, if populated. All 4 Sourcing Policies tables contain a Unit Cost and a Lot Size field, plus their UOM fields. The following screenshot shows these fields on the Replenishment Policies table:

- Unit Cost and its UOM field – specifies the variable cost for replenishing this product at this facility from this source. The cost can be a number, a step function, or a custom function.

- Lot Size and its UOM field – if a Lot Size is set, the facility needs to order integer multiples of this number from the source location.

- The first record in this table shows that DC_AZ can replenish all products from MFG_CA. The replenishment cost is $2.50 per unit and replenishment orders need to be placed in multiples of 50 units.

The Customer Fulfillment Policies and Replenishment Policies tables both also have an Only Source From Surplus field which can be set to False (default behavior when not set) or True. When set to True, only sources which have available surplus inventory are considered as the source for the customer/facility – product combination. What is considered surplus inventory can be configured using the Surplus fields on the Inventory Policies input table.

Finally, the Production Policies table also has following additional fields:

- Production Rate, and its Rate Quantity UOM and Rate Time UOM fields – together these can be used to specify how long production of the product at the facility takes. For example, when set to 50, EA, and HR, respectively, the production rate is 50 units per hour (= 60 min / 50 units = 1.2 min per unit).

- BOM Name and Process Name – if detailed production is modelled by using the Bills Of Materials and/or Processes tables, these can be associated to a facility – product pair through these fields.