Blog

Intelligent Greenfield Analysis: The Fastest Path to Network Design in 2024

PUBLISHED ON:

January 19, 2024

Subscribe to Receive the Latest Supply Chain Design Resources

Jim Wilson

Senior Director Product Management

When planning for new facilities or market expansion, reducing transportation expenses and emissions without sacrificing customer service is a tricky problem to solve. The obvious solution is through reducing the distance between you and your customers, but you can’t run an unlimited number of distribution centers.

Finding the balance between unlimited distribution centers and high transportation costs requires some serious math—how do you narrow down site options before you get into the optimization model? That’s where Greenfield analysis software comes in.

Greenfield analysis is commonly used for supply chain site selection, i.e. How many distribution centers (DCs) do I need, where, and what size?

We’re quite excited about Optilogic’s Intelligent Greenfield Analysis available in Cosmic Frog. Let’s have a look at the basics of greenfield, and how to use Optilogic’s intelligent greenfield analysis as a fast and simple, yet powerful way to narrow down facility options to a set of sensible candidates to analyze in a traditional network design model.

What Is Greenfield Analysis?

Sometimes called center of gravity analysis, greenfield analysis (GFA) is a supply chain network design method that combats the facility location problem.

Intelligent greenfield analysis examines market and industry conditions like your products, demand, and customer locations to determine how many distribution centers you need, where they should be located, and how large they should be to meet a defined service level.

Greenfield is typically a simpler precursor to traditional network design, which models detailed costs, capacities, policies, and constraints.

With greenfield analysis, you can start with hundreds of potential location candidates, and by applying parameters, rapidly narrow down to a set of five to 10 for detailed consideration.

To perform greenfield analysis with Optilogic, you’ll need only the following data tables:

- Customer location

- Customer demand

GFA uses this information to map out the ideal location for production and warehousing facilities and distribution centers.

Why Use Greenfield Analysis?

GFA is a simple, fast, and effective way to outline a strategic supply chain network design plan. Below are the best reasons to consider implementing GFA into your supply chain network design workflow:

Efficiency and cost reduction

GFA helps manufacturers identify how many distribution centers and factories are necessary to create a smooth and efficient supply chain.

The method establishes which customers can be serviced from a specific facility, the best number of facilities for a given supply chain, and the most cost-effective geographic location for each facility.

Because GFA can account for variables like your customer demand and their geographic locations, your budget, and even your customer service goals, the resulting DC placement minimizes transportation costs without sacrificing efficiency or customer satisfaction.

Reduced lead times

Because GFA identifies the most efficient locations for DCs using the distance between suppliers and customers and the resources available at each location, supply chain operations are more efficient with shorter lead times.

Better customer service

Optimized DC placement ensures locations can serve customers quickly and efficiently, which improves customer service.

Evaluate growth opportunities

Businesses can also use GFA to vet opportunities for expansion and capital expenditures such as new facilities and mergers and acquisitions.

Better risk management

Businesses can use GFA to choose DC locations less susceptible to supply chain disruptions like extreme weather events, political instability, or pandemic-related closures. The method can also be used to explore what-if scenarios for various demand and supply situations. These capabilities make GFA a good way to secure supply chain resilience throughout the economic volatility and global conflict expected in 2023.

What’s the risk rating on your supply chain designs? Optilogic’s Cosmic Frog provides a risk rating for every scenario.

Greenfield Analysis and Brownfield Analysis

Greenfield analysis is used to find the best locations for a specific number of new warehouses or facilities.

Brownfield analysis (BFA), on the other hand, is a way to predict how many facilities are necessary to meet new demand or which pre-existing locations should be retained to optimize output.

While GFA is used to design new supply chain networks, BFA is a tool typically used to restructure supply chains or alter the size of an existing distribution network. BFA is often used in situations like mergers or when new customers crop up in remote areas.

Cosmic Frog’s Intelligent Greenfield Analysis allows the user to do both greenfield and brownfield analyses.

Intelligent Greenfield Analysis with Cosmic Frog

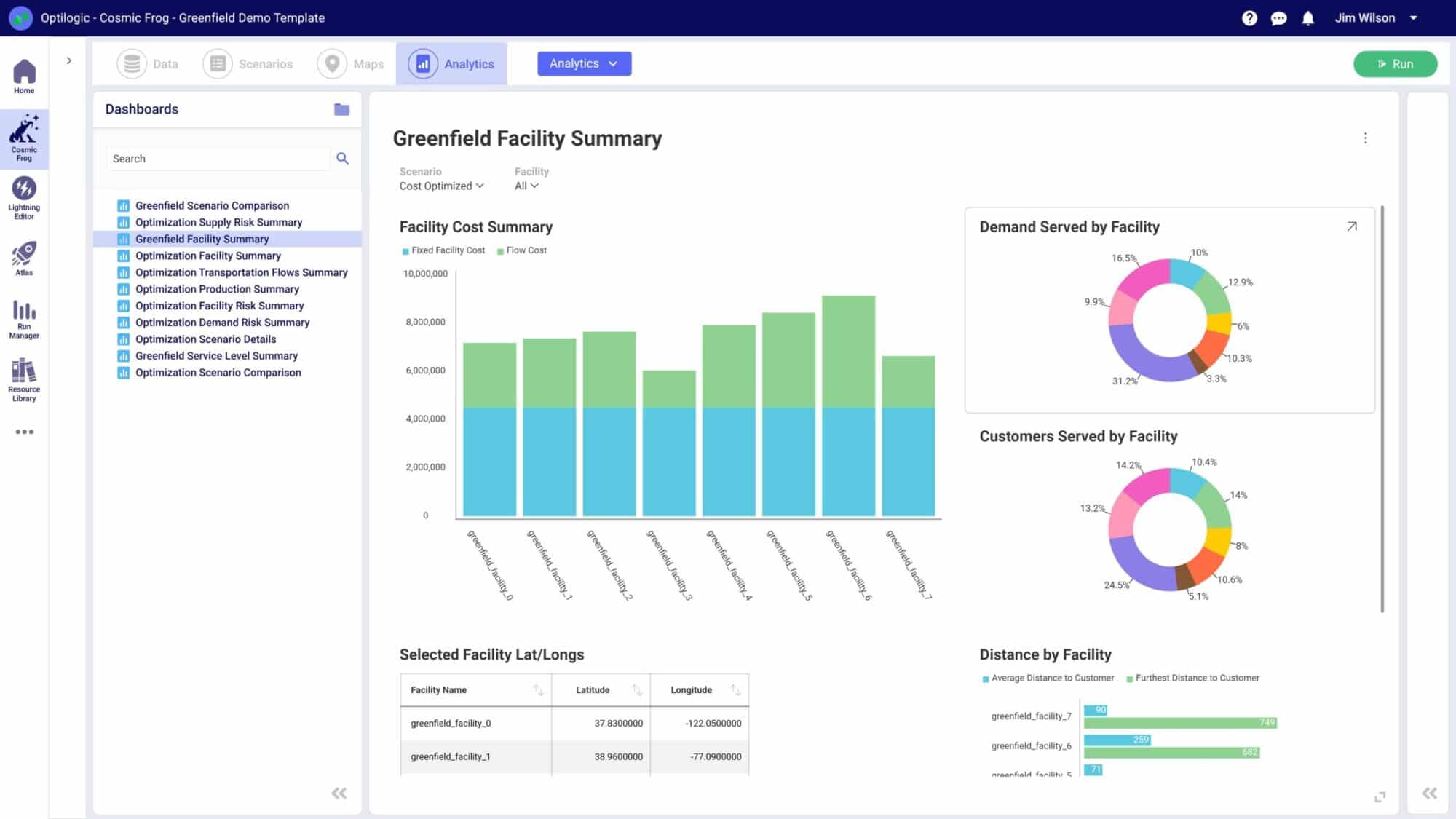

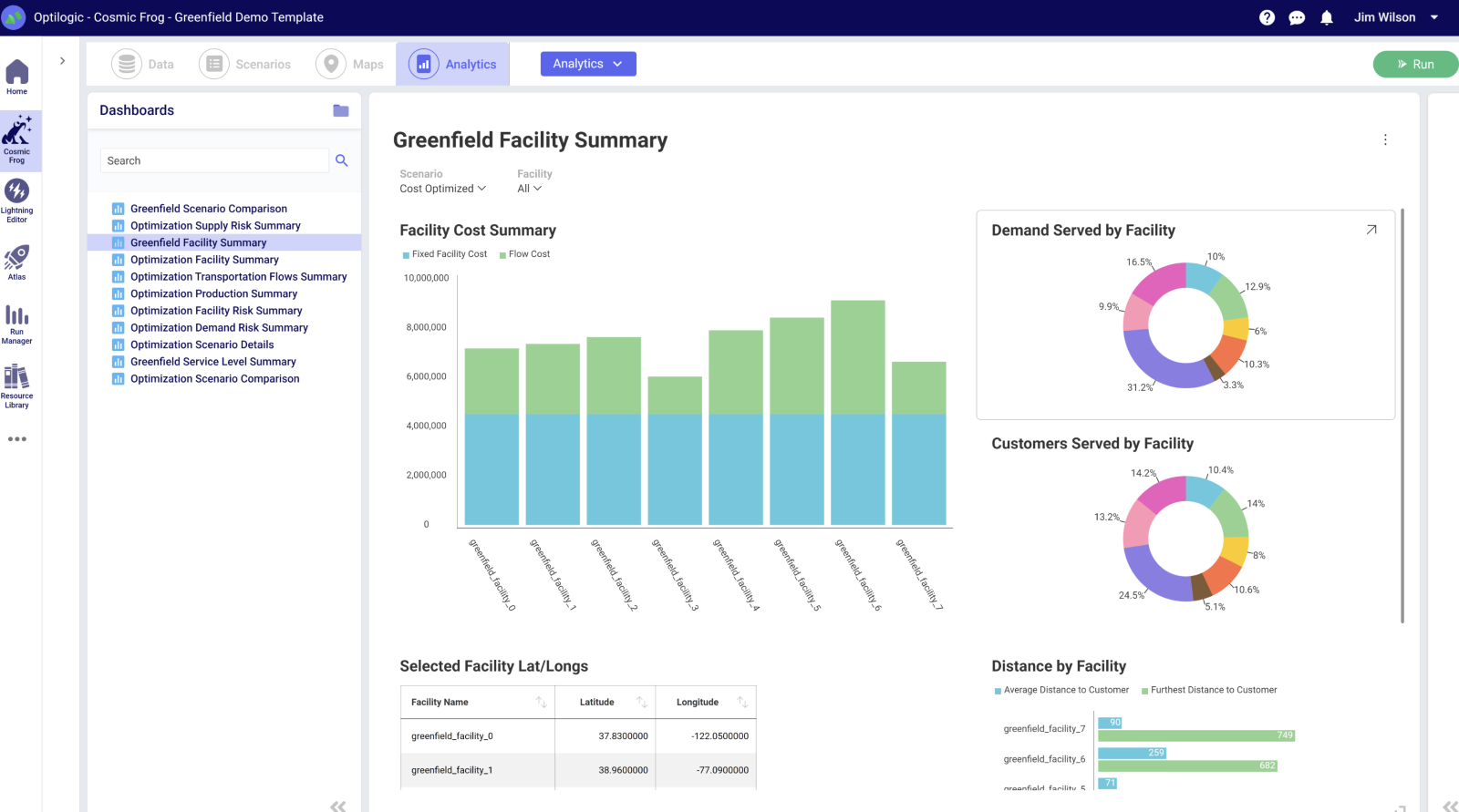

Optilogic’s Intelligent Greenfield Analysis offers capabilities above and beyond traditional greenfield analysis tools. You can:

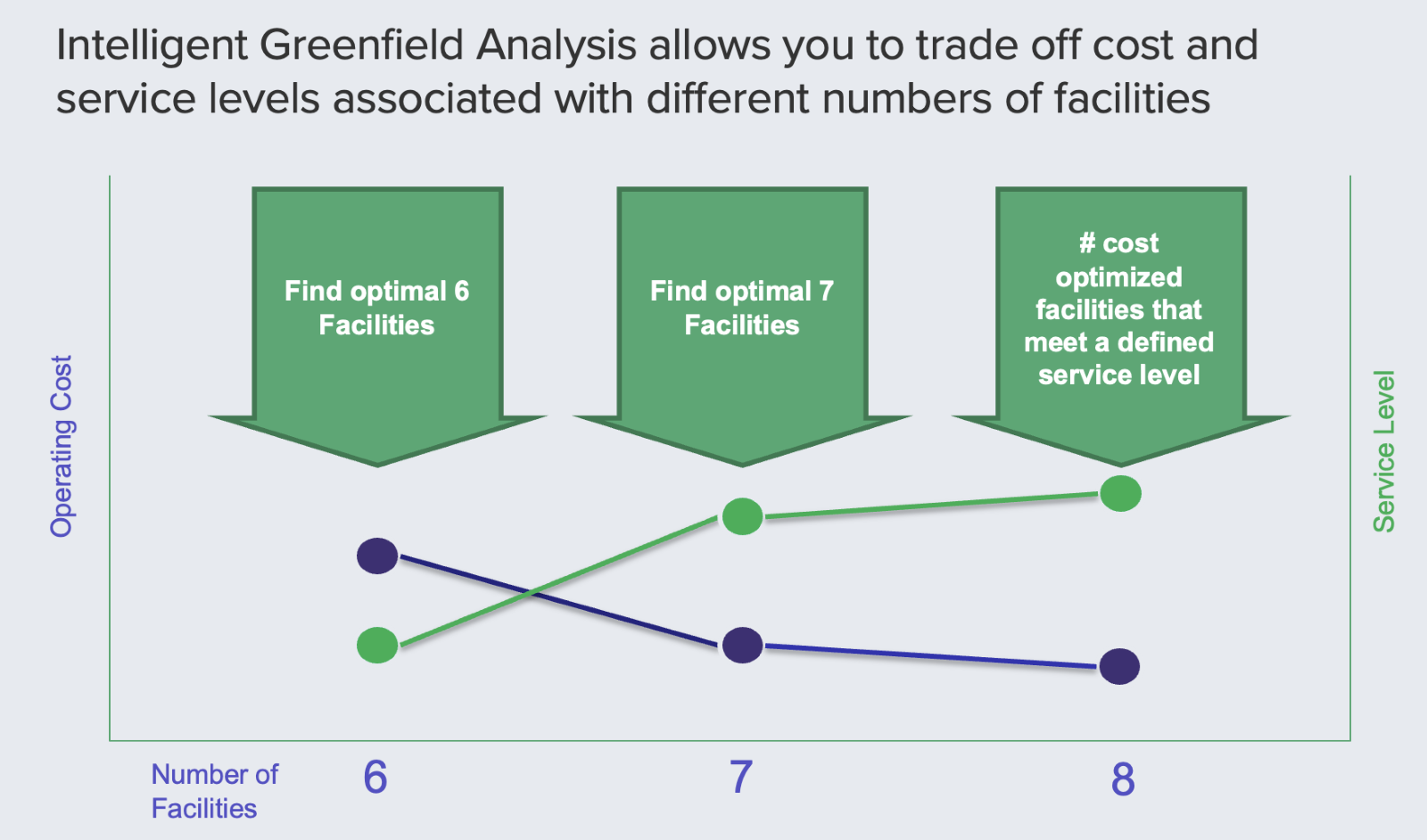

- Model and trade off fixed facility and transport cost: You may specify a fixed opening cost for new facilities as well as a per distance transportation cost. This allows the GFA engine to find the optimal number of DCs to minimize your total cost. If transportation costs are relatively low, GFA will open fewer DCs. If transportation is the main cost driver, GFA will open more DCs to reduce the average distance to customer.

- Consider multiple service level bands: You may specify a certain portion of customer demand to be served within certain range. For example, you may specify that 80% of demand must be serviced within 300 miles of a facility, the next 10% within 500 miles, and so on.

- Choose brownfield analysis: As we explained above, brownfield models existing facilities to help you determine where to open new additional DCs.

- Set capacity constraints for both existing and candidate locations

- Define the number of facilities to return: This way you can understand the optimum and specific number of facilities around the optimum by exploring the curve (see image below).

- Rapidly autogenerate many candidate locations

How Intelligent Greenfield Analysis Works

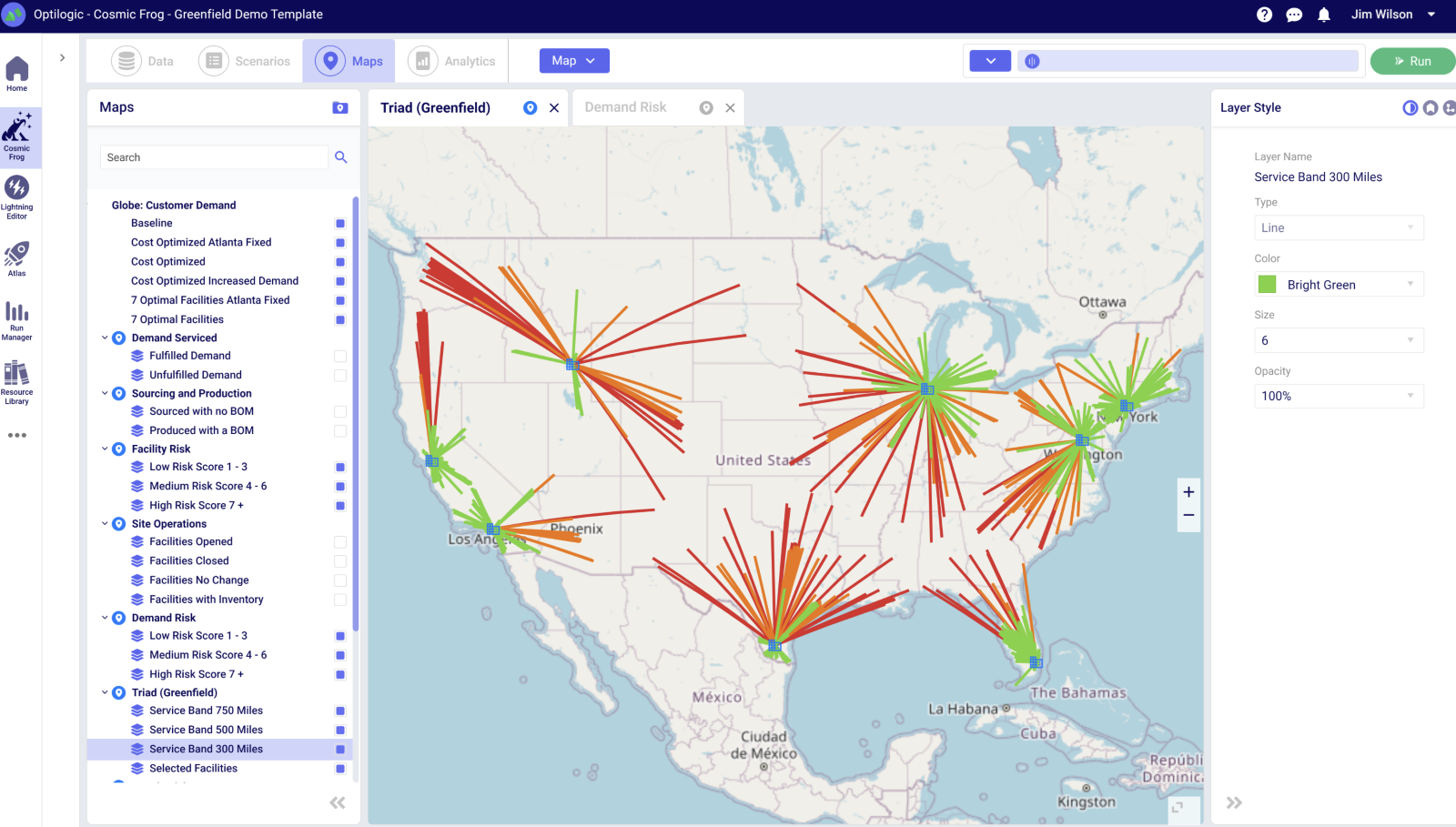

Step 1: Clustering and aggregation (optional): If you’d like to reduce scale and speed up the process, you can choose to cluster by geographical sectors.

Step 2: Optimization: GFA formulates a series of mathematical models and leverages an optimization solver to produce answers.

Step 3: Unrestricted DC placement (optional): By default, only customer locations are considered as potential greenfield candidates (this prevents placing candidate locations at the top of a mountain or in a lake). But if you decide to use this option, new distribution centers can be opened anywhere on the map.

Try Greenfield Analysis with Cosmic Frog

Ready to speed up your supply chain network design projects with greenfield analysis? Optilogic’s cloud-native supply chain design solution, Cosmic Frog, uses advanced optimization algorithms and data analytics to identify the best opportunities for simultaneously reducing transportation costs and distance and boosting supply chain efficiency.

Cosmic Frog can take your most complex supply chain design challenges and produce the most efficient design configuration in a fraction of the time other tools on the market take. This significantly reduces the time to value.

Create a free account to learn how Cosmic Frog gives you the ability to evaluate new designs across cost, service, and risk to select the best designs that improve resilience and shareholder value.

Grow Your Knowledge

Supply & Demand Chain Executive Names Mark Outslay of Optilogic as Recipient of 2025 Pros to Know Leaders in Excellence Award

Mark Outslay has fostered the customer success team at Optilogic through an exciting growth stage as they lead onboarding, training, project delivery, and ongoing support for numerous high-profile global companies.