Blog

If You’re Skipping this Important Step, You’re Not Doing Supply Chain Design Right

PUBLISHED ON:

March 23, 2023

Subscribe to Receive the Latest Supply Chain Design Resources

Due to the COVID-19 pandemic and global events like the war on Ukraine, it wasn’t long before the global supply chain as we knew it had nearly ground to a halt. Today, as we’ve emerged from the worst of it, we’ve learned some crucial lessons about how to design supply chains.

Too Many Organizations Fail to Truly Identify Risk Within Their Supply Chains

Sadly, companies working with less resilient supply chain designs have borne the brunt of the collateral damage from the supply chain collapse:

If you’re making strategic supply chain design decisions without considering risk, you haven’t learned much from the recent supply chain crises, and frankly, you’re not doing supply chain design right.

By widening your lens to consider potential risks to your network, your decision-making can address both financial and resiliency business objectives.

Start considering risk in your supply chain design!

Unlock Your Free Guide

Risk Has Been Missing in Supply Chain Design—Until Now

Risk management in supply chain has become a buzzy marketing concept because of the recent turmoil in the industry — suddenly, it seems as though the market is flooded with vendors talking about assessing and mitigating risk in supply chains. Until now, however, the focus has been on supply chain planning and execution, not on supply chain design.

Why is that? Common sense tells us that considering risk early should have a positive impact on eventual outcomes. Mostly, it’s been a question of lagging technology. Legacy supply chain design tech hasn’t provided a way to easily identify and quantify risks during the design process. So, risk hasn’t been a part of decision-making because we simply didn’t have a way to thoughtfully examine it.

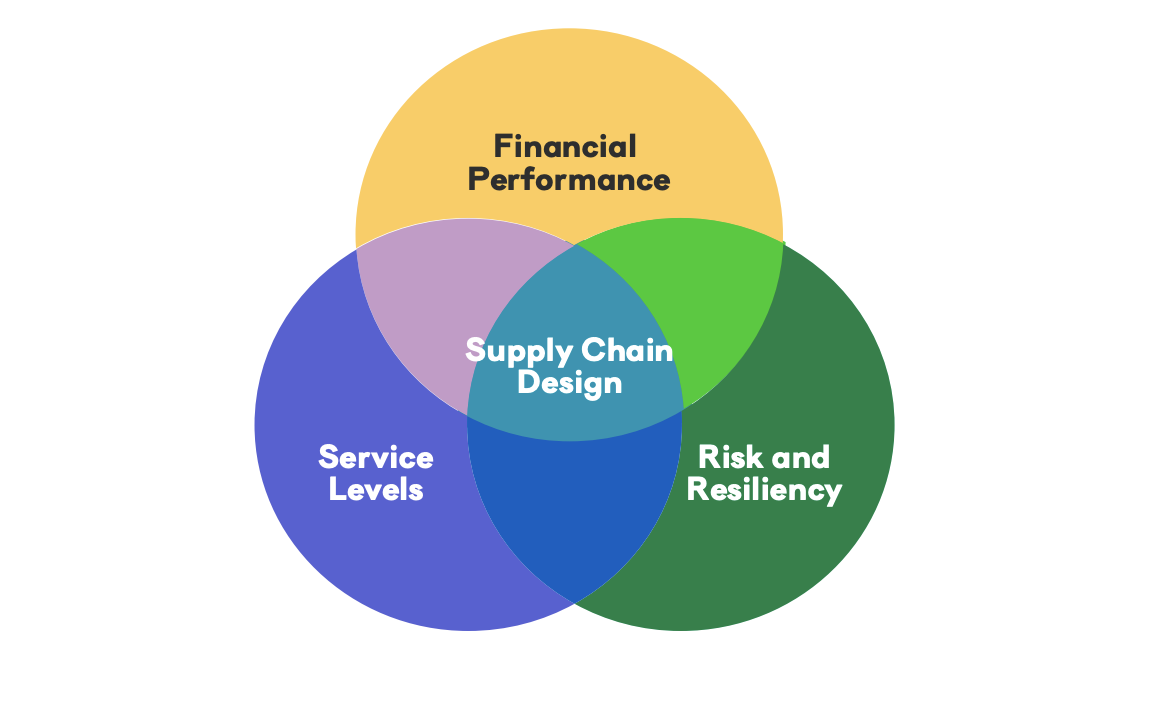

Instead, companies have compared different potential network designs and business policies based primarily on cost (and sometimes, service). Risk, though, has not been a part of the conversation at the design phase.

A Reactive Approach to Risk is Insufficient to for the Realities of Today’s Global Supply Chains

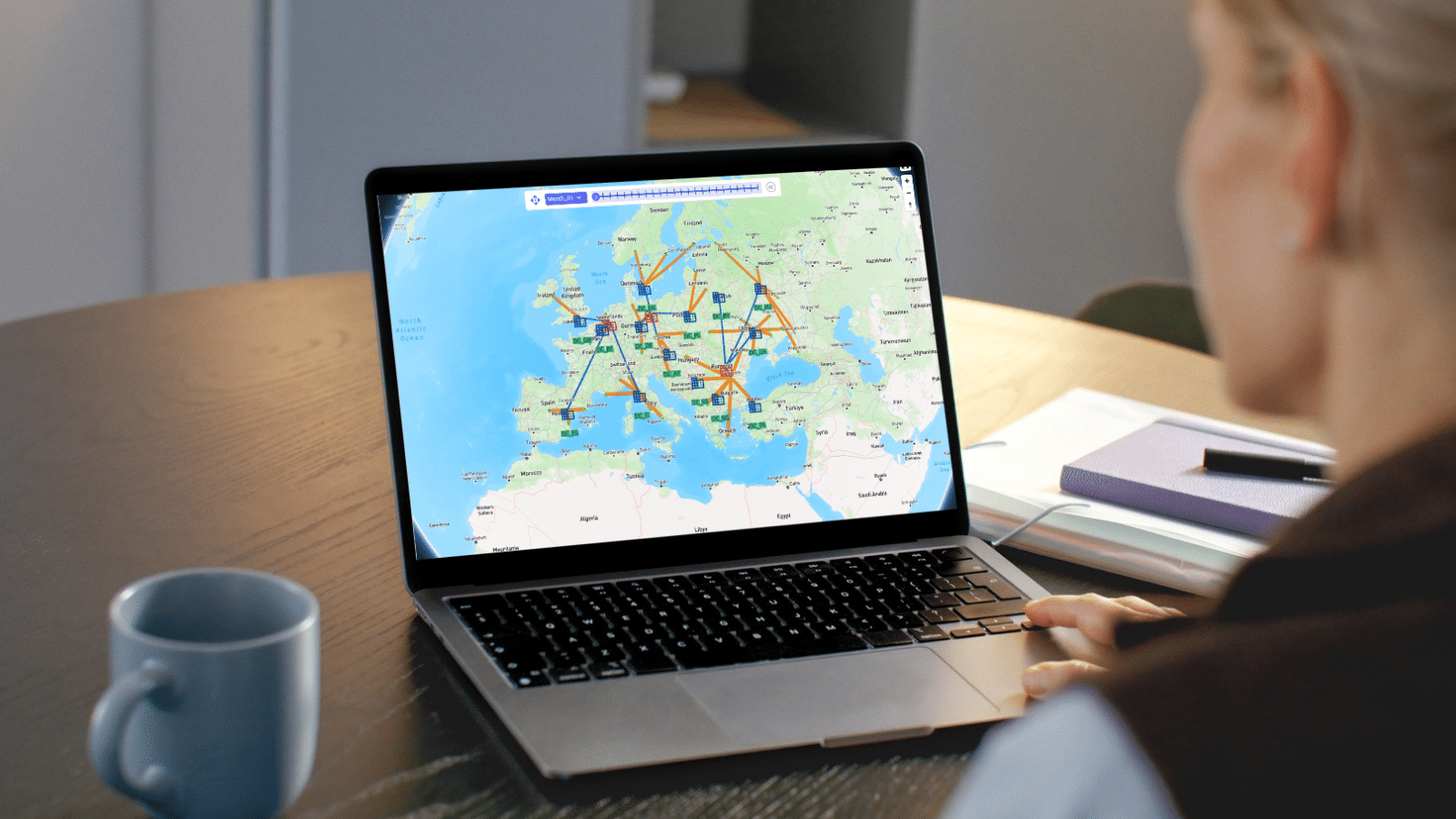

At Optilogic, we believe supply chain design must include risk. Our Cosmic Frog design platform enables companies to measure and quantify supply chain risk by providing comprehensive, contextual risk ratings for every scenario.

A resilient supply chain design requires three critical considerations: cost, service levels, and risk.

By considering risk in supply chain design, you’re empowered to make better decisions where modeled scenarios can be considered alongside finances, service levels and risk. This proactive approach to risk assessment and mitigation is far more beneficial than a reactive approach (waiting to assess risk in the planning and execution phase).

Optilogic’s risk engine breaks down risk into golden nuggets of data-driven analysis. Rather than limiting risk to a single focus on suppliers, the platform applies risk across the board — because every decision in the supply chain design process carries risk.

What Is Risk in Supply Chain Design?

When we’re discussing supply chain design, the concept of risk has a specific connotation. The Optilogic risk rating engine includes risks impacting decision-making in the supply chain design process; in other words, a focus on risks that might lead you to change your network design. That’s not to say other risks don’t exist or that they don’t matter—taking a proactive approach while making supply chain design decisions will organically help to mitigate or alleviate risks related to execution.

Optilogic considers risk in the big picture and breaks it all the way down to the granular level to help guide supply chain decision-making. The engine assesses risk and potential impacts according to analytic data collected by sources like the World Bank and the World Health Organization (WHO).

Here are two examples of the way the risk engine evaluates specific categories of risk in supply chain design:

Geographic risk

Geography can have a significant impact on risk. For example, the physical location of a supplier or facility can add risk related to the potential for natural disaster impacts from events like floods, droughts, extreme temperatures, or earthquakes. The distance from a customer, supplier, or facility to a nuclear power plant is another key consideration the risk engine analyzes.

The engine also considers geographic risk in the context of qualities like economic resiliency, political stability, and risk related to the strength of the local labor market. Optilogic helps determine whether alternate, less geographically risky locations could provide the same or similar financial outcomes and service levels.

Network design risks

Optilogic also assesses risks related to the network design or the policies governing the supply chain. Factors like the number of sources servicing a customer or facility or the percentage of storage capacity used can significantly impact risk and should be considered in decision-making. When these risks are higher, it could be beneficial to modify sourcing policies or reconsider product flows.

If you aren’t considering cost, service, and risk in the supply chain design phase, you’re simply doing supply chain design wrong. Modern supply chains need to be tougher than ever to withstand the global and local risk inherent in today’s political, environmental, and economic climate. Unlock your free guide to learn more about managing risk in your supply chain design.

Grow Your Knowledge

The 2025 CSCO Playbook: Leading with Influence, Speed, and Strategic Clarity

Discover how top CSCOs are leading in 2025 with influence, speed, and strategic clarity. This quick-read playbook reveals proven strategies to strengthen C-suite credibility, accelerate time-to-value, and build agile, resilient supply chains.

Lead Through the Shift: How Bold Supply Chain Design Turns Tariffs into Opportunity

Turn the new Trump tariffs into opportunity with supply chain design. Don’t wait for problems—use scenario planning for disruptions like tariff shocks, simulate possible outcomes, and create contingency playbooks to mitigate cost and risk.