Blog

5 Important Reasons to Define your Inventory Policies

PUBLISHED ON:

January 27, 2025

Subscribe to Receive the Latest Supply Chain Design Resources

María Angélica Marchesi

Director of Solution Design

Your supply chain design is a machine comprising various parts and elements that enable your organization to run efficiently, effectively, and productively. Inventory policies and rules play a critical role in your organization’s supply chain design. Getting these factors right is essential to creating the optimal supply chain for your organization.

In this post Optilogic supply chain design experts explore how and why to define inventory policies and rules that are unique to your businesses’ goals and needs.

The Challenge of Defining and Maintaining Inventory Values

No matter what you’re selling, inventory volume and delivery are the cornerstones of your success. Fulfillment efficiency, flexibility, resilience, and customer satisfaction—not to mention financial success—ride on having the right amount of product in the right place at the right time.

However, determining and maintaining optimal inventory proves a challenge to most organizations. Research from McKinsey found that 70 percent of executives aren’t satisfied with their inventory plans. They know their policies aren’t optimal, but they don’t know the next best step.

Where Most Supply Chain Design Software Falls Short

These inventory policy challenges have been a topic of conversation in supply chain design for years. Until recently, the industry hasn’t delivered a total solution to inventory management within supply chain design software.

Most inventory optimization solutions work off assumptions, Excel-based algorithms, and historical data with a limited capability to calculate all implications and uncover new opportunities. Including important supply chain behavior such as speed of product, etc. proves virtually impossible with this approach.

A few years ago, the inventory issue was too complex to solve. Identifying inventory drivers is a complex challenge requiring a ton of data and horsepower previously unavailable in traditional software solutions. Today, with cloud-based machine power, it’s possible, and it’s what Cosmic Frog facilitates every single day.

Establishing inventory policies within innovative supply chain design is a dynamic process; changing customer preferences, costs, etc., constantly affects your stock requirements.

Proactive, result-driven inventory management requires continuous monitoring, analysis, and adaptation. Continuous supply chain design ensures inventory levels remain aligned with business objectives while mitigating risks and maximizing efficiency across the supply chain.

The Importance of Defining Inventory Policies (and What Happens When You Don’t)

Poor supply chain inventory design affects both the customer and your supply chain efficiency. You should tailor your inventory strategy to each region and customer. When you don’t, you subject yourself to the following pitfalls:

-

Stockouts

If you don’t have enough inventory to meet customer demands, you’ll face debilitating stockouts, resulting in lost sales opportunities, damaged customer relationships, and potentially tarnished brand reputation. Depending on the product that is stocked out, you can lose market share and risk your company’s strategic positioning. You must deliver what you promise; your inventory policies ensure you do.

-

Obsolescence

Excess inventory ties up capital, incurring losses for stakeholders. This loss includes the costs of the product and its storage and transportation. When you overbuy a product, you are stuck with it past its usefulness or relevance, leading to obsolescence of your inventory.

-

Inefficiencies and Revenue Loss throughout the Supply Chain

When you don’t define inventory policies, you risk inefficiencies throughout the supply chain, including

- Increased lead times

- Suboptimal use of resources

- Higher transportation costs

- Diminished agility in responding to market fluctuations and disruptions

- Excess of capital investment

-

Poor Service and Failed Customer Expectations

Service is a critical factor in a balanced supply chain design. Suboptimal inventory policies jeopardize your ability to meet customer demands while maintaining operational efficiency and profitability.

-

Aggregated, Inaccurate Data

Using aggregation in defining inventory policies and rules assumes all members need the same attention and configuration. Would you assume all your main customers of any specific region place orders in the same way, with the same pattern, and should be treated with the same rules? No.

You need real-time data and balanced supply chain design to understand consumer needs and deliver as promised.

-

Neglected Cycle Stock

Most inventory solutions focus on optimizing the safety stock piece of inventory. Safety stock is an important part of the overall inventory strategy but is not the only one! Safety stock accounts for the unexpected behavior of the system, but how will you decide on the other piece?

Cycle stock is the result of decisions around speed, frequency and volume of inventory flowing into the network. Companies could change those parameters to also set up optimal cycle stocks and design supply chain flows not only for efficiency but also for service.

Benefits of Creating Inventory Policies with Cosmic Frog

Cosmic Frog boasts a powerful and innovative algorithm and analytics approach to solving inventory challenges. Our cloud-based, scalable platform allows us to gain powerful insights that grow with your organization.

We collect more data and address your problems in greater detail, such as demand and supply order variability. This massive volume of information allows us to answer all your questions and provide the thorough, data-based insights you need to make the next best move in your supply chain design.

Cosmic Frog answers the following inventory policy questions that are vital to creating an optimal design for your organization:

- What is the best way to balance service and supply chain costs?

- What are the optimal service targets?

- What is the optimal balance between transportation costs, inventory holding costs and service?

- If I re-design my inventory strategy, what are the optimal inventory policies?

- What is the Optimal Reorder Quantity and optimal frequency?

- What will be the fill rate per customer –– and even per order?

Below are a few highlights of Cosmic Frog’s supply chain design solution for defining inventory policies and rules:

Seamlessly Integrate and Automate

Cosmic Frog is easily integrated with other technologies. It enables process automation, which is vital to real-time supply chain efficiency.

Supply chain inventory design is a moving target. When the process is automated, you can be sure that you have the most updated data required for your supply chain design.

Ensure Accuracy

Our software uses granular SKU-level data, eliminating the need for aggregation. We deliver more data and a higher level of detail, showing accurate, actionable results you can implement immediately.

Enhance Speed

Cosmic Frog helps you increase your efficiency and save time by not having to pre- and post-process your data. Automation is at the core of our software, enhancing the speed at which you can evaluate and design your ideal supply chain.

Capture Operational Complexity

Our platform provides transactional-level detail for your orders. Many competitor solutions offer aggregated data, but Cosmic Frog lets you see what’s happening in real time at each facility. We provide data on the detailed costs of your products, whether they’re moving within a warehouse or in transport to the customer. We have the day-to-day data to capture your operational complexities and empower you to optimize your supply chain design accordingly.

Identify More Creative Solutions

Cosmic Frog generates large-scale results of 600+ possibilities. We give you visibility into the entire solution space and the flexibility to choose from various options. Our innovative scenario modeling helps you understand barriers and range of movement, gives you a more comprehensive understanding of the consequences of your supply chain design choices, and shows you how resilient your supply chain will be under various circumstances.

Save Resources and Increase Profits with a Comprehensive Solution

Cosmic Frog helps you better consider influencing factors and simplify supply chain design complexity. The software evaluates network interactions between critical variables like demand and supply variability, service, and replenishment strategies to create a supply chain that balances your organizational priorities.

How to Define Inventory Policies and Rules in Cosmic Frog

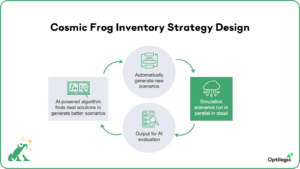

- Cosmic Frog harnesses AI and cloud hyperscaling to run numerous simulation scenarios to pinpoint your best-fit solution.

- Detailed service metrics, along with financial performance, can be included in the search for the optimal scenario.

- AI-powered algorithms continually refine scenarios to pinpoint the best solution given business goals. Use the best inventory strategy to inform your inventory planning system.

Learn more about setting inventory policies and rules with Cosmic Frog