Blog

Risk Management: The New Essential in Supply Chain Management

PUBLISHED ON:

October 24, 2022

Subscribe to Receive the Latest Supply Chain Design Resources

You’ve heard over and over again that supply chains must be agile and resilient. Every article, blog post, and podcast stresses the importance of mitigating risk and being able to quickly respond to the disruptions that today’s world continues to produce. It’s clear that Risk Management is a hot topic in supply chain management, but companies are often left scratching their heads on how to stay ahead of future risks instead of just reacting to disruptions that can be seen on the horizon.

The past few years have created a perfect market opportunity for new companies to emerge that help organizations monitor for elevated risk levels. There are exciting new solutions that utilize AI and data analytics to identify risk in a supply chain, based on current events and trends. Adding these capabilities to the supply chain process will no doubt accelerate a business’s journey toward a more resilient supply chain. However, the recent innovation has been focused on decision-making and mitigation in the tactical and operational time period, providing companies with only a short time frame to adjust and pivot, which limits the options for mitigating the risk. The processes established to monitor real-time risk factors will always remain important in our world of volatility and uncertainty, but it needs to be complemented by a more proactive approach to risk identification and mitigation.

Supply Chain Design Must Include Risk

Supply Chain Design is the process used to design or review the structure of a network, along with the policies that govern and control the behavior of a supply chain in order to most effectively match supply to demand. Companies almost always focus on minimizing cost in design decisions, and thankfully, more companies are also considering the importance of meeting or exceeding service levels. Why not consider the riskiness of any given decision or scenario? The future of supply chain design must include risk in order for the world to become proactive in its risk mitigation efforts. Decisions on how to structure and operate a supply chain should be made by understanding the tradeoffs between financials, service, and risk. Therefore, risk must be identified and measured in the supply chain design process and your design technology solution should be able to provide this visibility and quantification of risk for each scenario. We are well past the days of only focusing on lean, efficient, and cost-effective networks.

While machine learning and predictive analytics have made tremendous progress and have an exciting future, we will never have a crystal ball that will predict future supply chain disruptions with 100% accuracy. But what we can do is identify areas of a supply chain that are vulnerable and risky and then use advanced modeling techniques to test the impact of these potential risks. Understanding the potential impact of a disruption in your design process creates the opportunity to be proactive in reducing the risk or being prepared with plans for how to adjust operations (if the disruption is realized). How can an organization understand the potential impact, test mitigation strategies, and establish processes to support agility? Let’s use this example below of using the supply chain design process and modern design technology to be proactive against risk.

An Example: Proactive Risk Management

Imagine if you considered placing a new distribution center in a location that is susceptible to natural disasters and in this case, let’s use a location that could find itself in the path of a hurricane. By conducting scenario modeling (with simulation) you can understand the impact on your finances and service levels should a hurricane take this site offline for a few days, for a few weeks, or a few months. Use a combination of optimization and simulation to then explore options for how you would maintain business continuity given each potential situation. For example, you might be able to temporarily fulfill orders from safety stock at another location or use excess storage capacity elsewhere for the period of time that this site is offline. By understanding the feasibility of each option, the cost, and the impact on your service, you might decide to turn one of the scenarios into a contingency plan to use if a disruption occurs. However, there is a chance that your analysis might reveal that it is impossible to fulfill some orders or meet your service levels if this site is offline for anything longer than 2 weeks. You explore moving the location inland by 300 miles, but this scenario is flagged by the software as risky because of the shrinking labor market in that county so you decide against the relocation. Further scenario modeling is done to analyze an adjustment in which products are serviced through the proposed location. By reducing the number of high-priority, high-margin products that are serviced by this DC, the impact of this location going offline in the event of a hurricane or tropical storm is significantly reduced. This is an example of proactively identifying and mitigating risks, and creating a plan that provides agility for potential disruptions.

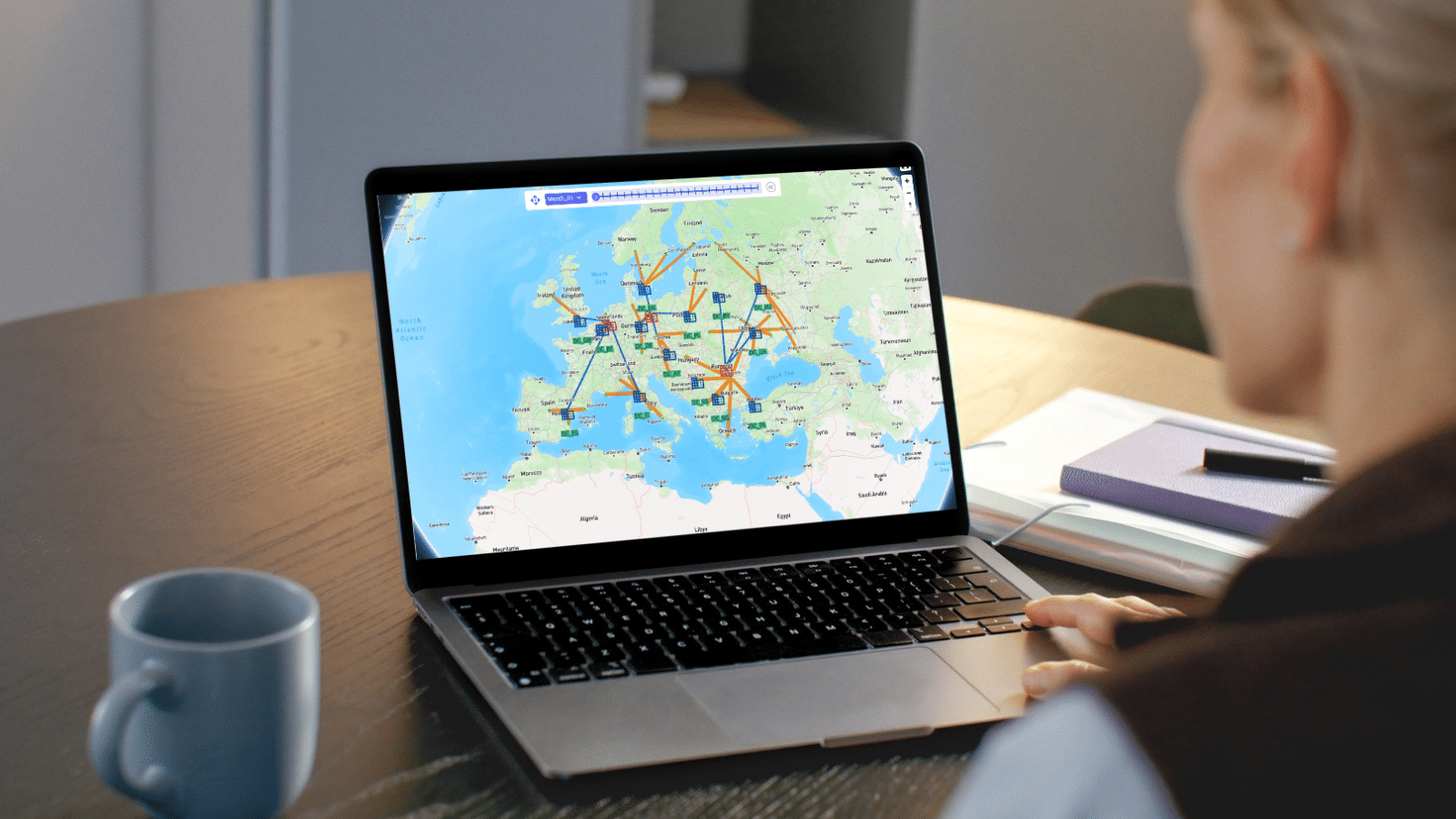

Optilogic’s Supply Chain Design platform contains an optimization, simulation, and risk engine, which provides a risk rating for each and every scenario. This allows organizations to bring risk identification into the design process, enabling decision-making based on financials, service, and risk. To learn more, request a demo or reach out for a chat

Cosmic Frog: A Supply Chain Network Design that Balances Cost, Service, and Risk.

Create a Free Account

About the Author

Renee Thiesing

Renee has over 20 years of experience working in the software industry, most of which has included a focus on simulation and applying this technology towards process improvement and enablement of digital transformations. With a focus on manufacturing and supply chain, she has worked with customers across verticals, such as CPG, Pharma, Aerospace & Defense, and Food & Beverage. Renee has held a variety of roles throughout her career in software and is currently the VP of Strategy and Risk Solutions at Optilogic.