Blog

What Is Supply Chain Network Design?

PUBLISHED ON:

May 5, 2023

Subscribe to Receive the Latest Supply Chain Design Resources

John Ames Jr.

VP Business Development

What Is Supply Chain Network Design and Why Is it Important?

Your supply chain design affects every aspect of your organization’s success. You can’t rely on antiquated systems to design supply chains that work in a modern market. Understanding the importance of supply chain network design empowers you to establish smart, resilient supply chains that grow with you and adapt to constant market fluctuations. Here’s what you need to know to get started.

Defining Supply Chain Network Design

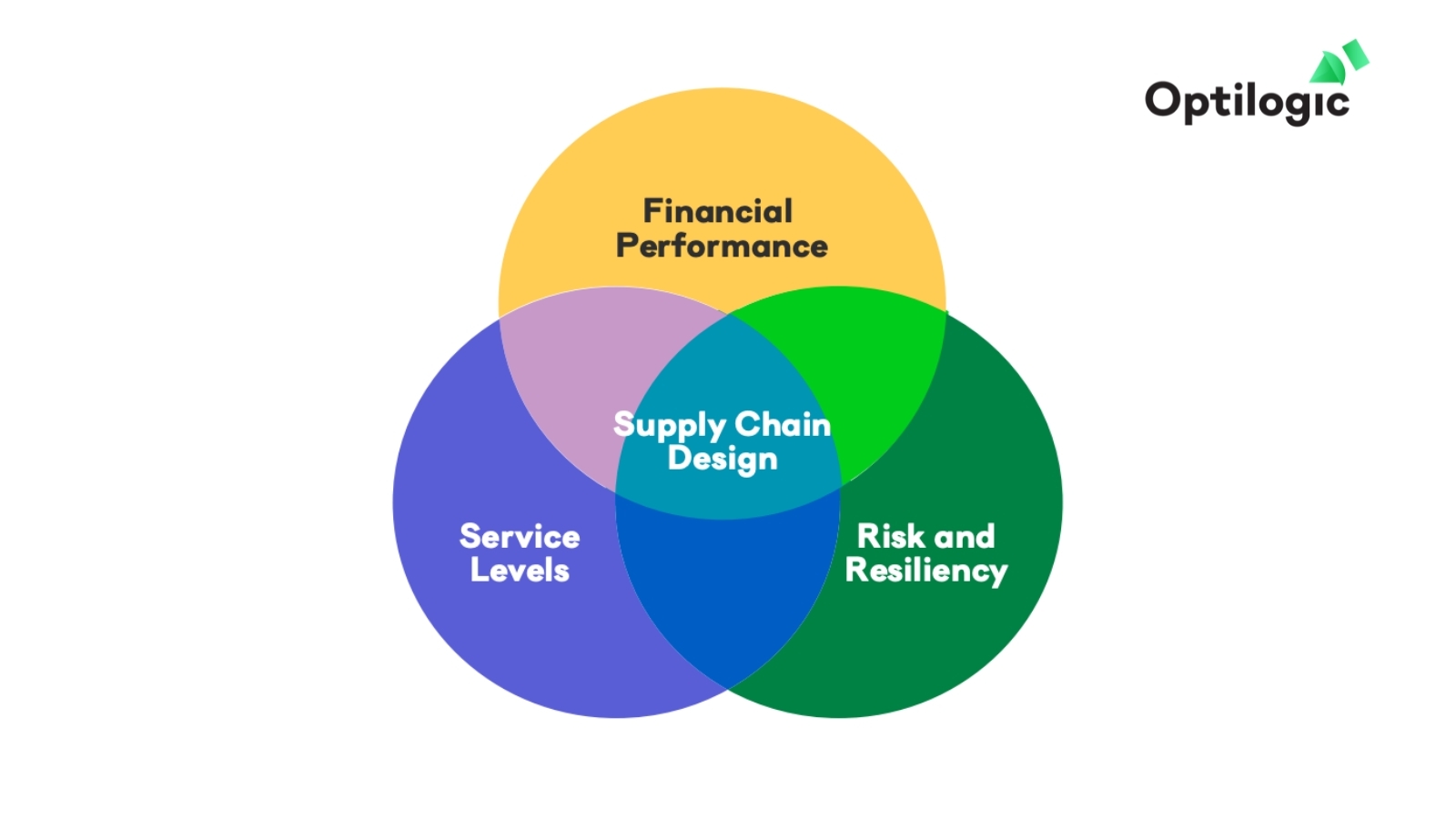

Supply chain network design is modeling the future state versus the as-is state. It’s an ongoing process to evaluate the end-to-end supply chain to make data-driven decisions using advanced analytics and human knowledge, balancing cost, service, risk, and ESG elements.

Herbert Simon said that to design is to devise courses of action aimed at changing existing situations into preferred ones. At Optilogic, this is how we view supply chain network design: it shapes the end-to-end flows of your supply chain into optimal solutions for your organization.

When considering supply chain network design, many organizational leaders think about facility location, warehousing, or plant logistics. It includes these elements, but it encompasses so much more.

Within your supply chain design, you can make various policy decisions: distribution, inventory, sourcing, and service-level policies and transportation modes. These policies don’t involve changing the physical structure of the supply chain but working toward fine-tuning how you might be setting policies in your planning and execution systems.

Every aspect of your production–sourcing, manufacturing, transport, warehousing, distribution, and all the micro-steps and elements in-between, including your policies and constraints–make up your supply chain design.

Supply chain network design directly shapes your KPIs. And with effective design, you can reap rewards quickly. Supply chain network design doesn’t have to have a 10-year timeline. You can carry out long-term projects with short-term implementation. Smart supply chain network design ties the policy element into a planning solution by having a design technology that acts as a digital model to replicate future states of policies.

Going Beyond Cost-Optimization in Supply Chain Network Design

Historically, organizations haven’t considered variability or risk in supply chain network design. Their entire network was designed around cost. We saw the global consequences of ignoring supply chain resiliency during the pandemic and its aftermath. Companies that didn’t understand the fragility of their supply chains suffered. And many never recovered.

Supply chain network design must consider more metrics than just cost. Service, risk, volatility, and ESG metrics are essential components of your supply chain network design.

And while optimization is critical to a successful supply chain network design network, it’s not the only element affecting your design choices. Simulation should heavily influence supply chain network design.

Simulation allows you to model at a transactional level with variability in mind and understand how your future-state supply chain can perform much better than a simple optimization model. Unfortunately, many companies don’t prioritize time to run variable simulations. This leaves organizations vulnerable to preventable disasters resulting from fragile supply chains.

Blog: What’s the Difference Between Scenario Modeling and Simulation?

Optilogic’s platform allows you to simulate supply chain models to answer the “what-if” questions and scenarios within your end-to-end supply chain. Our models help you test your systems, refine your strategies, and test the feasibility and impact of proposed design changes.

Supply Chain Network Design Requires Defining Your “Good Supply Chain”

When companies embark upon intentional supply chain design, they must answer this question: What’s a good supply chain network design for this organization at this moment as well as two, five, and 10 years in the future?

Most companies don’t understand what a good supply chain network design means for their organization. And that’s because it’s complicated and nuanced and involves identifying and evaluating metrics across the organization, including production, sourcing, inventory, transportation, and more.

In addition to the logistics elements, organizations must also consider emerging social metrics in supply chain network design, including sustainability and fair trade.

Getting these metrics right isn’t easy. It takes data. And many legacy companies aren’t there yet. They’re still using Excel or gut feel to design their supply chains. Organizations must have access to organizational data to determine the end-to-end metrics that guide departmental goals.

Unique supply chain network design allows companies to move away from simple warehouse location problems to planning, production, and distribution policies linked to planning and execution.

Working on the Cosmic Frog supply chain design platform empowers you to create supply chain designs that go beyond the basics, considering your network from every possible perspective and scenario and providing the data required to move forward.

Data-Driven Supply Chain Network Design

Companies want answers quickly. Many times, data pieces come with timelines. You need to understand where your data comes from, and you need that data to drive your organization to better metrics.

Usually, the data required for supply chain network design is the same data running the business. And according to Deloitte, only a minority of companies have become insight-driven organizations. If organizations don’t have the data needed to create their supply chain network design, they likely don’t have sufficient data to make informed decisions regarding the operations of the business.

Supply chain network design is data-driven. You need information regarding demand, cost, replenishment, production, shipping, and more. And if you use benchmark data, you’re simply guessing because that data may not be current or accurate for your organization.

Ongoing Collaboration in Supply Chain Network Design

Supply chain network design is an ongoing series of initiatives that drives organizational excellence. Most companies view supply chain network design as something you do once every three or four years, designating one or two individuals running optimization models.

Because supply chain network design impacts the entire organization, all stakeholders need to be involved–just like they think about planning, manufacturing, or sourcing and how to design procedures, policies, structures, and flows on an ongoing basis.

Supply chain network design should be a continuous collaboration. That means you need a team or ecosystem of partners reviewing the continuous metrics that define a good supply chain for your organization. This team, or Center of Excellence, is responsible for tweaking, refining, and making combinations of long-term and short-term decisions around design.

Many companies are functionally and departmentally siloed. They have metrics that mean something to individual departments but don’t understand how those metrics fit into an end-to-end supply chain. Design thinking skills are in short supply, so companies must be creative in defining their supply chain network design teams. Partners, contract employees, and 3PLs should be part of the ecosystem of experts that organizations use, along with their internal experts who know their data and supply chain in detail.

Because Cosmic Frog is cloud-native, the platform makes it easy to collaborate on data and the outputs of these models, both internally and externally if you’re working with consulting partners and suppliers. Models and metrics are easily updated, and you have visibility to define what works on a quarter-by-quarter basis.

Cosmic Frog lets you connect to external data and create dashboards representing your unique metrics and KPIs. You can connect the organization much more efficiently and accurately than legacy technology. Design, planning, and visibility should be working synchronously, and that’s what Optilogic accomplishes with Cosmic Frog.

Resilient Supply Chain Network Design Built for You

You know that in today’s market, supply chain network design is foundational for your success, regardless of your product, industry, or market.

Optilogic Cosmic Frog delivers supply chain solutions built for resiliency. Our three-in-one design uses optimization, simulation, and a risk engine to provide insights that guide intelligent, sustainable, robust supply chain network design.

The Cosmic Frog platform runs multiple models in parallel, providing results faster and more accurately than any other technology on the market. Our team provides real solutions to meet real needs. Intuitive interface, robust workflows, and easy scenario modeling make supply chain network design more straightforward, faster, and more effective. And it’s free to get started.

Sign up for a free account and try the future of sustainable, resilient, optimized supply chain network design.